By Josh Cosford, Contributing Editor Vacuum technology is the quintessential method for safe and careful material handling in various industries, from packaging to glass manufacturing. Vacuum cups and pads are gentle and soft, lifting even the largest material while barely contacting the surface. By creating a vacuum inside the cup, the pressure differential draws the […]

Engineering Basics

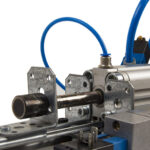

5 reasons your pneumatic cylinder isn’t working

By Josh Cosford, Contributing Editor Pneumatic cylinders are essential in various industrial applications, providing the mechanical force needed to move loads, automate equipment, and perform countless other tasks. However, pneumatic cylinders encounter issues that impede their performance like other machine components. When your pneumatic cylinder isn’t working as expected, it can lead to downtime, reduced […]

Understanding air flow and FRLs

By Josh Cosford, Contributing Editor Pneumatic systems are widely used within industrial environments to power machinery and equipment, providing reliable and efficient performance. The Filter-Regulator-Lubricator (FRL) is vital in maintaining optimal air quality and pressure within these systems. However, when selecting an FRL, one must not overlook the significance of understanding FRL air flow characteristics, […]

Rid your packaging lines of UKTs (Unnecessary Knob Twisters)

Follow these five steps to prevent tampering and ensure effective and correct process adjustments for pneumatic components. Steve Bain, Industry Segment Manager – Food and Beverage, Festo North America In modern automation systems, the need for frequent process adjustments poses the risk of unwanted device tampering, often referred to in exasperation by plant managers as Unnecessary […]

What type of miniature pneumatics technologies are available?

In the realm of fluid power engineering and manufacturing, innovation knows no bounds. The advent of miniature pneumatics has ushered in a new era of precision and efficiency, enabling a wide range of industries to benefit from compact and surprisingly powerful pneumatic systems. These miniaturized marvels have found their way into various sectors, using low […]

Pneumatic valves: How do they work?

This content was updated on April 6, 2023, with a new section dedicated to proportional valve technology. Compressed air pneumatic systems require methods of safe and precise control of the actuators unique to their accoutrement. Although the medium is fluid, just as hydraulic or process water systems, the execution of control is different in many […]

How do you repair pneumatic cylinders?

By Josh Cosford, Contributing Editor I’ve seen many pneumatic cylinders in my fifteen years in fluid power. From pancake to ISO and from NFPA to compact round line, there are as many types of air cylinders as there are applications for them. With so many cylinders and ways to use them, there are many ways […]

Why do pneumatic cylinders fail?

By Josh Cosford, Contributing Editor It would be easy to assume all cylinders fail in the same fashion — that hydraulic cylinders bypass and air cylinders experience bent rods. However, it’s a false assumption because the nature of their operation and intended application differ. Sure, a hydraulic cylinder can bypass but not as easily as […]

Why is compressor control important?

When controlling screw compressors, the goal is to try to keep all the running compressors fully loaded except one. And the one running partly loaded (called trim) is selected as the one having best part load efficiency characteristics. When there are only two or three compressors in a group, it is quite easy to set […]

How do air motors work?

By Josh Cosford, Contributing Editor A motor is any device designed to convert one form of energy into rotational mechanical force. For example, an electric motor converts electrical potential into mechanical torque, and a hydraulic motor converts hydraulic energy from pressure and flow into mechanical torque. And an air motor converts compressed air into that […]