Last month, I had the pleasure of attending Pack Expo in Las Vegas for the first time in about five years. I’ve always enjoyed that show, seeing all the packaging machinery and conveyors operating, watching the pneumatics and motion control technologies do what they do best. But I did notice one thing this year — […]

Blog

Compressed air fail: Poor sealing methods

If you have ever done leakage detection with an ultrasonic leak detector you will get to know the common leak locations. If you have no detector, there is no excuse these days, excellent equipment is available for you to purchase at a reasonable price, go get it! A common sight — or rather sound — […]

When is it time to retire an air compressor?

When is it time to retire a compressor? Your old unit may have served you very well over the last few decades, reliably providing a seemingly endless supply of compressed air. Some units, like the unit in Fig. 1, have been around so long that they have almost become part the family. This design is […]

Compressed air fail: Turn on to save

In the compressed air world, there are quite a number of energy savings features available to be installed on air compressors and air dryers. Often, these cost a premium to buy — but will very quickly pay for the added cost through reduced electricity bills. A recycling facility purchased an energy efficient heated blower style […]

Six simple ways to improve your compressed air system

By Ron Marshall Compressed air is one of the most expensive ways to supply energy to facility tools and equipment. This is due to the inherent inefficiencies in the process of compressing air — the biggest product is heat and the secondary output is compressed air. While this is disappointing, there are still things that […]

How do you adjust dew point on air dryers?

Question: I need your advice about how to adjust the dew point for the dryers which are equipped with a dew point controller. Also, for those not having a controller, how can we determine which dew point is the best setting — -40 or -70? Answer: This is a complicated question. The method for adjusting […]

Compressed air fail: Ventilation design

A plastics manufacturer was having constant trouble with his desiccant air dryers. No matter what he did, they would constantly set off dewpoint alarms, which was very annoying. He called in a compressed air auditor to have a look. The auditor shot temperatures and found that the discharge of the compressors was too hot. Outputs […]

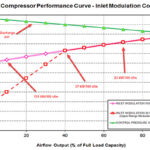

Compressed air fail: A modulation nightmare

John, the maintenance manager of a wood products company, was very proud of his Number 3 compressor. It has been operating for years, racking up more than 200,000 run hours — and was so trouble free, it was almost scary. Of course, John kept it maintained, changing oil and filters on a regular basis, fixing […]

Compressed air fail: Fire system

A large industrial plant fell on hard times and had to reduce their production shifts to only 8 hours per day, 5 days per week. The compressed air system remained running full time 24 hours a day, including weekends, due to the need to supply the plant’s dry fire system with air pressure. The total […]

Should I repair or replace my aging air compressor?

What should you do when it comes time to decide if you should repair or replace your aging air compressor? There are a few things you should consider. Air compressors are like motor vehicles — if they are used continuously, hardly shutting down, they should not be expected to run for a long time without […]