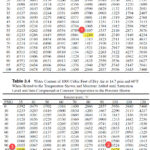

Question: On our air compressor, we have a drain at the bottom of what looks like a filter, located after the air cooler. The drain failed so we turned it off … how important is it anyway? Answer: Here is the data you need to know about condensed water flow in compressed air systems (taken from […]

Blog

What is VSD cooling?

In the compressed air world, the hottest thing in the market lately has been the introduction of variable speed drive controlled compressors. Being hot (as in popular) is good — but being hot as in temperature is not so great. These units, if installed appropriately, can stabilize the air pressure, and save significant amounts of […]

Designing optimum pneumatic systems for food & beverage packaging

These tips not only adhere to food safety guidelines, but also serve to improve machine utilization and performance. By Steve Bain, Food and Beverage Industry Segment Manager, Festo Before describing the four pneumatic automation design tips for food and beverage packaging applications, it is a good idea to answer a fundamental question: Why apply pneumatic […]

Compressed air fail: Units conversion

Have you heard the story of the Gimli Glider? An Air Canada flight ran out of fuel on July 23, 1983, at an altitude of 41,000 feet, midway through the flight. The cause? It was a mix up of pounds and kilograms when calculating the weight of fuel to load for the flight. (Give it […]

Compressed air fail: Cycling dryer savings

Your equipment controls can sometimes tell you some good stories if you observe carefully. And sometimes tell of problems. Consider two thermal mass cycling air dryers installed in a foundry. Thermal mass cycling dryers are designed to reduce the energy consumption of the internal cooling system by turning off and on (cycling) the refrigerant compressor […]

Compressed air fail: Blowing reduction

It is very common in an industrial facility to have compressed air blowing applications installed at various locations to provide cleaning of sensing eyes and scanners. But it is important to keep in mind that this blowing demand can add up quickly — especially if there are many of these applications installed within the plant. […]

Why is condensate disposal important in compressed air systems?

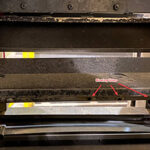

A wood products company had a two-compressor system installed on a mezzanine. Under the compressors and dryers were the piping and storage receivers. Each tank and each compressor had timer drains installed to expel the condensate that forms when the compressed air cools in the compressor aftercooler, piping, and storage vessels. The outlets of these […]

Compressed air fail: Flowmeter position

A local food company was resizing its compressed air system while renewing its plant operations. To get the sizing correct, the plant maintenance foreman purchased a flow meter to measure the output of the compressors. The meter was installed with a data logger to capture the flow profile of the plant. The readings showed that […]

Watch out for dangerous blow wands

Despite years of warnings — and the development of OSHA standards — there are still many dangerous compressed air blow wands in service at facilities throughout the world. Countless injuries and even deaths could have been prevented if safer devices were used or the blowing eliminated altogether. Fig. 1 shows a wand used to clean […]

Using CAGI data sheets for refrigerated air dryers

If you are shopping for a refrigerated air dryer, it is a good idea to consult the Compressed Air & Gas Institute (CAGI) published data from the manufacturer before you buy. If you buy a non-cycling air dryer, the unit will consume about the same power no matter what — even if the associated air […]