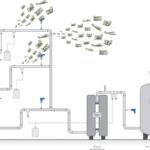

Measuring and repairing compressed air leaks can easily reduce energy costs by 10 to 20%. Compressed air is used in factories all over the world to control machines, processes, and pneumatic equipment. It is a safe and easily available medium and can be used in all possible places via hoses and pipes. However, compressed air […]

Featured

Compressed air fail: Crud in the lines

A compressed air auditor had a system of measuring devices that was monitoring a compressed air system located in a metal foundry. Pressure, flow, and compressor power were all monitored to help determine if the system was running efficiently and effectively. An additional set of instruments were added to the monitoring suite due to some […]

Free pneumatic positioning optimizes gripping

Pneumatic grippers are revered for being an economical, easy-to-maintain solution with high force density. However, force control and precision can prove challenging, especially when handling delicate parts and parts of different sizes. Sensory feedback is essential in such applications to measure parameters such as the force applied, object position, and speed. Position sensing is especially […]

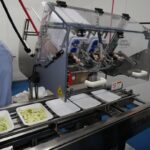

One Cajun beef, please, but hold the air compressor oil

No one wants air compressor oil contaminating production. And in food processing applications, quality and safety are essential. E2M Kitchen, a fresh and ready-to-eat meal provider, knows this all too well. The Charlotte-based company significantly evolved its food preparation and packaging process for creating gluten-free, dairy-free, and preservative-free meals. Every tool used in its production […]

Distributed electro-pneumatics streamline equipment designs

Machinery builders and OEMs save space and improve functionality by applying electro-pneumatic I/O and solenoid systems throughout their equipment. By: Chip McDaniel, AutomationDirect For machine builders and original equipment manufacturers (OEMs) alike, there is an increasing push to deliver smarter, more modular, and physically compact systems. Among the many design choices required to make this […]

A primer on when to use pneumatic vacuum pumps

By Josh Cosford, Contributing Editor Vacuum technology is the quintessential method for safe and careful material handling in various industries, from packaging to glass manufacturing. Vacuum cups and pads are gentle and soft, lifting even the largest material while barely contacting the surface. By creating a vacuum inside the cup, the pressure differential draws the […]

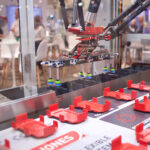

Precise and localized pneumatics complement advanced motion controls in packaging machines

Packaging machine manufacturer Coesia and its sister companies rely on system integration for efficient, precise and fast operations. With a focus on streamlined systems that reduce pouch or carton handoffs and offer the ability to move non-standard sized materials, Coesia companies R.A. Jones and MGS turn to modern motion control systems married with precision pneumatics […]

5 reasons your pneumatic cylinder isn’t working

By Josh Cosford, Contributing Editor Pneumatic cylinders are essential in various industrial applications, providing the mechanical force needed to move loads, automate equipment, and perform countless other tasks. However, pneumatic cylinders encounter issues that impede their performance like other machine components. When your pneumatic cylinder isn’t working as expected, it can lead to downtime, reduced […]

Understanding connected pneumatics and how they benefit manufacturers

In future, updating pneumatic circuits through the IoT will help manufacturers stay current and benefit from the opportunities available to them. Contributed by Mike Parzych, Product Marketing Manager • Norgren Smart, internet-connected devices have become increasingly significant in all areas of life, and industry is no exception. The use of automation, artificial intelligence, and advanced analytics […]

Are pneumatic technologies at risk of becoming obsolete?

Last month, I had the pleasure of attending Pack Expo in Las Vegas for the first time in about five years. I’ve always enjoyed that show, seeing all the packaging machinery and conveyors operating, watching the pneumatics and motion control technologies do what they do best. But I did notice one thing this year — […]