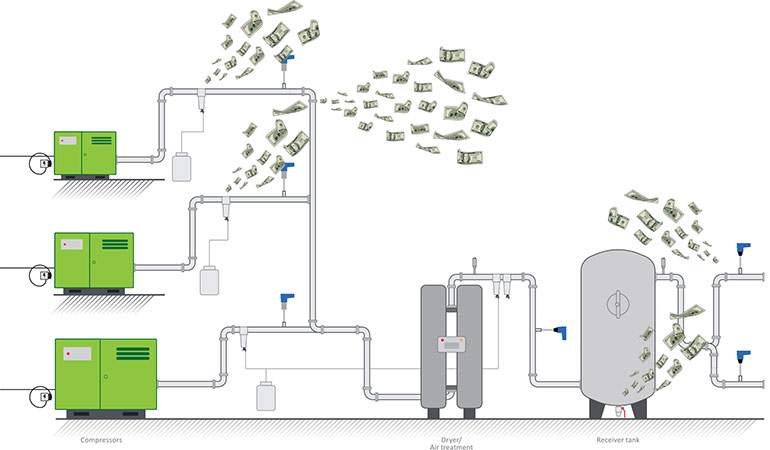

Measuring and repairing compressed air leaks can easily reduce energy costs by 10 to 20%.

Compressed air is used in factories all over the world to control machines, processes, and pneumatic equipment. It is a safe and easily available medium and can be used in all possible places via hoses and pipes. However, compressed air is one of the most expensive energy carriers. Still, significant savings can be made on compressed air costs with proper compressed air leakage management and monitoring. To start simply: detecting and repairing leaks can immediately result in an energy gain of 10 to 20% and once expanded with compressed air monitoring and optimizations, the savings can even reach 50%.

What makes compressed air one of the most expensive energy carriers? Pascal van Putten, CEO of VPInstruments explained it this way. “When compressing atmospheric air to a pressure of 90 to 100 psi, 75% of the electrical energy absorbed in the compressor is lost as heat. Pressure loss and leaks, among other things, ensure that the electrical efficiency of the entire compressed air installation is only 7.5 to 15%. This can be improved, and you would expect companies to do everything they can to achieve this. Yet, this is not the case and every year billions of dollars in energy are wasted worldwide, simply because many companies neglect to repair leaks and to optimize the efficiency of their compressed air installation.”

Approximately 5% of all electrical energy used worldwide is converted into compressed air; within the industry itself, this is more like 10%. The generation of this enormous amount of energy contributes to CO2 emissions and climate change. For that reason alone, it is sensible and even necessary to reduce compressed air consumption. Additionally, improving compressed air installation efficiency goes straight to the bottom line.

Leakage management: low hanging fruit

Addressing compressed air leaks is a critical, yet often overlooked aspect of optimizing energy efficiency in industrial settings. Despite its simplicity and relatively low investment requirements, detecting and repairing leaks can yield significant cost savings. Van Putten underscored the straightforward nature of leak detection and repair. “It is absolutely not complicated and does not require high investments to start detecting and repairing leaks,” he said.

Van Putten referred to an example installation that operates 8,760 hours/year. The system pressure is 100 psi and the electricity costs are $0.10 per kWh. In this instance, ten holes of just 1/16 in. cost the company $10,500 per year. If the ten holes were 1/8 in., the costs increase to $41,900. “In practice we often encounter hundreds of leaks of all different sizes, and also larger than 1/8 in.! You can imagine what the total financial losses in that case will be,” van Putten said.

“To detect and repair such leaks, you will spend a few thousand dollars on a simple measuring system and parts such as gaskets, hoses, and quick couplings. We therefore call leaks the ‘low hanging fruit’ in compressed air installations. Easy to detect, easy to repair -— and repairing them produces immediate financial profit. Companies often have an external agency carry out a leak audit in which all leaks found in the factory are marked with TAGs. It is not uncommon that when the auditor returns to the factory a year later, the TAGs he applied are still there. So, nothing has been done about it while the leaks and associated costs continue as normal.”

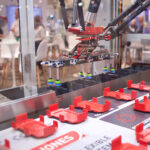

Prevent production downtime

Apart from the financial benefits, an even more important reason exists to ensure that the compressed air system functions optimally and efficiently. A reliable compressed air supply is crucial for the continuity of production processes. The right amount of flow and pressure determine the correct operation of production machines. However, leaks contribute to pressure loss.

Insufficient pressure can not only lead to machine downtime, but also affect the quality of products. Errors in packaging or inconsistent texture/taste of foods can inevitably lead to costly recalls. Not to mention the damage to your image. In addition, if pressure drop is incorrectly diagnosed as an equipment defect, there is a chance that investment in new equipment will be required. This entails (unnecessary) additional investments that could have been better utilized elsewhere. Optimizing compressed air systems not only increases energy efficiency, but also establishes the foundation for a reliable and well-performing production process.

Leak detection methods

When a hydraulic line leaks in a factory and the puddle of hydraulic fluid on the floor continues to grow, it is evident the problem should be solved as quickly as possible. Not so with compressed air leaks. After all, it is “just air,” so it isn’t considered an emergency. It will get taken care of “some day.” Postponement leads to cancellation and the financial and (possible) operational consequences of such a nonchalant attitude will now be clear.

There are various techniques and leak detection methods to detect leaks quickly and easily in compressed air systems, ensuring minimal disruption to operations and maximum cost savings. The most common are:

Ultrasonic leak detection — This is a commonly used method for locating compressed air leaks. Ultrasonic detectors can capture high-frequency sounds produced by air leaks and make them audible to humans, allowing maintenance teams to accurately locate, mark and repair the source.

Compressor monitoring — A commonly used additional method for detecting (the risk of) leaks is to carefully check/monitor the compressor. This method compares the current performance of the compressor with the achievable/expected performance according to specification. Structural deviations in a negative sense can directly indicate leaks.

Venting test — This method measures the time it takes for a compressed air system to reach a specified pressure drop. If this is carried out periodically, a trend-based insight can be obtained into the overall system efficiency.

Trend analysis — The use of flow meters and monitoring systems provides valuable data about possible leaks. By analyzing the measured and trended data, it becomes possible to identify areas within the plant where significant changes have occurred over time or acutely. This may be caused by (sudden) leaks. This suspicious zone can then be specifically examined using ultrasonic measurements.

Downtime consumption — Plenty of factories still do not produce on weekends. But nevertheless, they still see their compressors kick in during the weekend. Measuring compressor power consumption during downtime is a good indicator of the amount of leakage in a factory.

Leaks in compressed air systems can occur anywhere. They often occur at couplings and in (older) hoses. But incorrectly mounted or corroded pipes, fittings, filters, regulators, and lubricators (FRLs) are also common locations. Leaks can also occur in production lines at control and shut-off valves, flanges, cylinder rod gaskets, and thread seals.

“It is crucial that the maintenance team can independently carry out leakage repairs without the need for approval ‘from above’ every time,” van Putten said. “After all, this has a very slowing and demotivating effect. It would be useful to introduce a guideline stating that repairing something that costs less than three to six months of energy waste can be carried out immediately and without formal approval. In addition, the savings accrued after repairs in the subsequent period can be added to the energy savings budget. This creates a self-sufficient, cyclical fund within the organization, with the result that solving leaks and further optimizing the compressed air network will make an essential contribution to increasing profits.”

Pressure reduction

After leaks have been resolved, it is important to analyze and optimize the compressed air installation in a targeted manner. With the help of permanent monitoring, for example, the current compressed air consumption is measured and monitored, and changes are signaled in a timely manner. VPInstruments has developed the real-time VPVision monitoring system that, in combination with VPFlowScope flow, pressure and temperature meters, provides information that allows a maximum cost-effective compressed air system to be achieved.

For safety reasons, a (too) high working pressure is often set, for example 7 bar. But is that necessary? Sometimes machines that require high pressure have long been replaced. By reducing the pressure in small steps and monitoring the system and machine performance full-time for correct operation, it is often possible to reduce the pressure by 14.5 to 21 psi. Remember that every 14.5 psi pressure reduction means a 7% reduction in energy costs.

VPInstruments

vpinstruments.com

Leave a Reply