Pneumatic grippers are revered for being an economical, easy-to-maintain solution with high force density. However, force control and precision can prove challenging, especially when handling delicate parts and parts of different sizes. Sensory feedback is essential in such applications to measure parameters such as the force applied, object position, and speed.

Position sensing is especially important in dynamic environments. But determining position is just one piece of the automation puzzle. Adjusting position based on feedback is how pneumatic systems optimize operations and improve efficiency. Specifically, free positioning increases flexibility and makes pneumatic grippers adaptable to changing or for use in less structured applications.

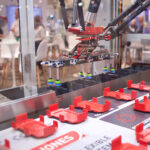

A new type of pneumatic positioning device (PPD) from SCHUNK allows such free pneumatic positioning with pneumatic grippers. The setup includes a gripper, sensor, and PPD. Prefabricated PLC function blocks simplify commissioning. The PPD was developed as an accessory and is controlled via IO-Link. Modifications or special variants of the gripper are unnecessary, making retrofitting existing processes easy. This is an optimal solution for any gripper application requiring flexibility, such as robot applications that move workpieces of different sizes or in close proximity.

This flexible control enables users to optimize cycle times, as the gripper fingers no longer need to move to their end positions before and after each gripping operation. The device also avoids collisions with closely positioned workpieces by pre-positioning the gripper fingers. The gripping force can also be adapted by adjusting the output pressure, which provides clear advantages for gripping workpieces of varying sensitivity. Even more gentle gripping is possible by adjusting the gripper jaw speed, which reduces the gripping impulse.

Inside the unit, four integrated high-speed 2/2 valves, integrated electronics, and the position sensor, which is installed on the gripper, ensure a closed control loop. The sealed design with IP67 makes the PPD suited for industrial environments. The unit can be installed end-of-arm and, therefore, achieve precise positioning with short hose lengths. This ensures a positioning accuracy of up to 0.5 mm.

The PPD is available in three versions that differ in the flow rate of the internally installed valves. Size and weight always remain the same. An IO-Link sensor by SCHUNK or all common analog sensors from other suppliers can be used as sensors.

SCHUNK

schunk.com

Leave a Reply