FRLs are key in treating and conditioning downstream components to ensure high air quality in most pneumatic machinery.

By Josh Cosford, Contributing Editor

Often forsaken, the FRL appears in the bills of materials for commissioned pneumatic machinery, only to never be touched again or considered by the end-user. Even when penciled into the design of such a machine, the selection criteria for FRLs is digital at best … “did we add one? Good, done.”

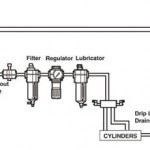

Although you may overlook the FRL as the place in the circuit where you adjust pressure and from which water sprays, its value is only trumped by the actuator, directional valve and air compressor. The FRL — standing for Filter Regulator Lubricator — conditions the air sent to each pneumatic component in your plant. From air tools to packaging and from automation to machine tool, the uses for the FRL are as plentiful as there are applications.

In a nutshell, FRLs are used to treat and condition air for downstream components, most of which need dry yet lubricated air at a stable pressure less than the output of the main compressor. There is no harm running your air-powered beer can crusher from your portable compressor, but the needs of sophisticated automotive paint systems or massive torque wrenches command high-quality air with consistent properties to ensure high performance.

Filter comes first for a reason

Although airline components come in many forms, the most common is an assembly offering the combination of filter, pressure regulator and lubricator. Most often cut from the combo is the lubricator, as not all systems call for any aerosol oil lubrication for their components. Some airline components such as locking safety valves, drains or dryers are common, but this article will stay true to the three components of the FRL.

The filter’s importance cannot be overstated, as the precision and reliability of a circuit’s innards must be ensured. Contamination affecting the health of your system can be generated from the ambient air drawn into the compressor, from the compressor doing the heavy lifting, from the air receiver and from the distribution piping.

Most air compressors draw primarily through a filter, because just as contamination can damage downstream components, so too can the particles damage the compressor, itself sometimes the single most expensive piece of equipment in the plant. However, these large suction filters are designed to flow with little resistance leaving all but the smallest particles removed but do not protect downstream components from the high volume of microscopic particles from atmospheric dust and microorganisms.

As well, particle contamination is also internally generated, sometimes from the compressor itself. And if the distribution system is old, oxidation and friable rust forms and breaks off, infecting downstream valves, actuators and instrumentation. It helps to install a filter regulator assembly directly after the air dryer of the compressor, which removes the bulk of externally sourced particles and ensures stable pressure for the entire circuit.

Filters remove more than particles because contamination exists in more forms than microscopic chunks of matter. The filter of every FR or FRL uses uniquely shaped internals to swirl and disperse liquid contaminations such as water and oil. Liquids collect at the bottom of the filter bowl and these contaminants exit through the drain at the bowl’s bottom, either manually or automatically, depending on the complexity of the filter. The low cost of airline preparation equipment easily allows for automatic drains, although attention should still be paid to them, ensuring malfunction doesn’t allow fluid to accumulate and pass downstream.

The removal of fluids from a standard filter occurs at less than 100% efficiency. Applications with sensitive components such as electronics, or advanced motion control constituents need a higher level of liquid removal. Equally important are industries where contamination removal nears perfection — medical, pharmaceutical, food processing, and electronics. The coalescing filter removes aerosol oils and vapors sourced from compressor lube oils, residual cutting oils, condensed moisture, and other dissimilar oils and their solutions. Coalescing filters are sometimes used as the primary filter in the FRLs designated to the above applications and industries, although often they exist as a single component only when and where needed.

The removal of fluids from a standard filter occurs at less than 100% efficiency. Applications with sensitive components such as electronics, or advanced motion control constituents need a higher level of liquid removal. Equally important are industries where contamination removal nears perfection — medical, pharmaceutical, food processing, and electronics. The coalescing filter removes aerosol oils and vapors sourced from compressor lube oils, residual cutting oils, condensed moisture, and other dissimilar oils and their solutions. Coalescing filters are sometimes used as the primary filter in the FRLs designated to the above applications and industries, although often they exist as a single component only when and where needed.

In the location after the compressor, a high-flow filter is more important than anywhere else in the circuit. At 100 psi, you waste 1% of the input energy for every 1 psi of pressure drop through the filter. So, if you’re running a 50-kW compressor with your undersized filter squandering 15 psi of pressure drop, then you’re blowing 7.5-kW right off the top, and you haven’t even considered downstream components yet. And if you’re paying 13 cents per KW/h, like we do here in Ontario, you’ll be paying thousands of dollars per year just because you chose the incorrect size of filter.

Regulators ensure stable pressure

You won’t choose a lubricator to be mounted directly after the pump, unless of course every downstream part needs lubrication. More likely your filter will just be paired with a regulator. The regulator is important to promote stable pressure (and therefore flow) downstream of the compressor. Most components — especially actuators — need stable pressure drop for smooth, predictable motion. Running multiple machines with multiple cylinders, rotary actuators or motors from full compressor pressure will result in unstable plant pressure higher than what most machines demand.

An air regulator senses downstream pressure at its secondary (controlled) port, which acts upon a diaphragm or piston, itself pulling up a plug or poppet. As controlled pressure rises to near the spring value of the regulator, the poppet at the primary (inlet) port is pulled upward to choke inlet flow, thereby reducing the rate of flow. The reduced flow rate results in lower downstream pressure. The movement of the control assembly is dynamic and incessant, yet imperceptible; regulated pressure is simply maintained as adjusted if upstream flow and pressure are more than is needed.

When there exists the potential for over-pressurization on the governed side of the regulator valve, a relieving function must be chosen. Relieving regulators use a vent to exhaust excessive pressure, especially helpful when downstream functions are static, but need safe, stable pressure. Should heat or loads cause pressure to rise in an unsafe or uncontrolled fashion, venting some air keeps pressure at its set level, even when the inlet port is completely blocked.

Selection and sizing is critical

Each machine or drop line location should have its own FRL, because each machine has its own pressure, flow and conditioning requirements. Your pneumatic tools, for example, require high pressure and flow with airline lubrication. In fact, some tools such as high-speed sanders and impact wrenches use upwards of 10 scfm at 90 psi, making them the most demanding air consumers in your shop. Air flowing at a high velocity through an FRL results in high-pressure drop, meaning less energy is available to do work but wastes itself as heat.

A 1-in. drive impact wrench running full steam at 10 scfm at 90 psi regulator setting from an undersized ¼ in. ported FRL will likely lose 20 psi just through flow alone, as noted in the accompanying graph, leaving the wrench with only 70 psi with which to create work. A more appropriately sized ½-in. FRL will waste only a few psi to flow the same rate, leaving nearly all 90 psi available for torquing nuts.

Let the application determine lubrication

Air tools are lubed to extend life and enhance performance, and the easiest way to guarantee oil delivery comes from the lubricator. The mist-type lubricator flows incoming air across a venturi, itself attached to a drop tube dipping into the bowl of tool oil. Partially pushed and partially sucked, the oil vaporizes as it exits the venturi, carried away with the air flowing to the outlet port.

Some tools, machines or components may need specific forms of lubrication, making FRL’s important at each drop leg or machine in your plant. Spool valves, cylinders, air motors, rotary actuators and any other pneumatic item with sliding, moving or rubbing parts, will function more accurately, reliably, and efficiently when well lubricated.

Because FRLs are so important and prominent, their refinement, performance, quality, and cost are all available in one package. Every pneumatic manufacturer makes them, providing you competitive choices for every price point and performance level. When in doubt, choose the highest performing option for your application, and even as pricing rises, so too does your return on investment. A high-flowing, finely filtered FRL with an efficient lubricator will always pay off in the end.

Leave a Reply