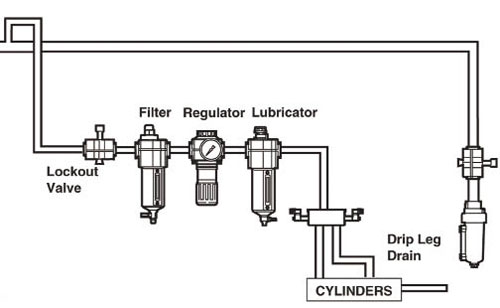

Air leaving a compressor is hot, dirty, and wet—which can damage and shorten the life of downstream equipment, such as valves and cylinders. Before air can be used it needs to be filtered, regulated and lubricated.

An air line filter cleans compressed air. It strains the air and traps solid particles (dust, dirt, rust) and separates liquids (water, oil) entrained in the compressed air. Filters are installed in the air line upstream of regulators, lubricators, directional control valves, and air driven devices such as cylinders and air motors.

Air line filters remove contaminants from pneumatic systems, preventing damage to equipment and reducing production losses due to contaminant related downtime. Downtime in an industrial plant is expensive; often it is the result of a contaminated and poorly maintained compressed air system.

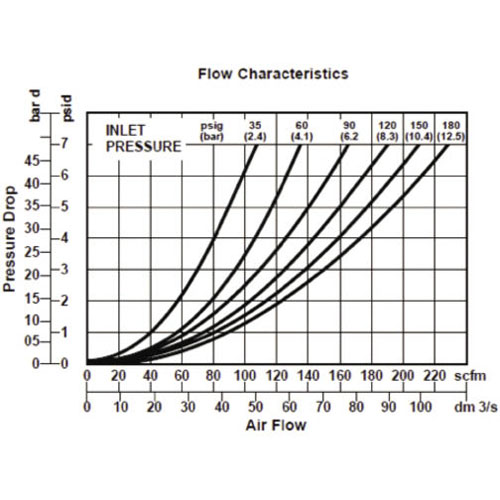

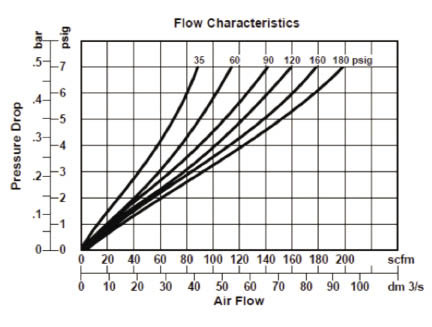

Selecting the proper size of filter for any application should be done by determining the maximum allowable pressure drop, which can be caused by the filter. The pressure drop can be determined by referring to flow curves provided by the manufacturer.

There are three types of filters. General purpose, Coalescing (oil removal), and Vapor removal. General Purpose are used to remove water and particles, Coalescing to remove oil and Vapor removal to remove oil vapor and odor.

Pressure regulators reduce and control fluid pressure in compressed air systems. Regulators are also frequently referred to as PRVs (pressure reducing valves). Optimally, a pressure regulator maintains a constant output pressure regardless of variations in the input pressure and downstream flow requirements. In practice, output pressure is influenced to some degree by variations in primary pressure and flow.

Pressure regulators are used to control pressure to: air tools, impact wrenches, blow guns, air gauging equipment, air cylinders, air bearings, air motors, spraying devices, fluidic systems, air logic valves, aerosol lubrication systems and most other fluid power applications.

Regulators have a control spring which acts on a diaphragm to regulate the air pressure. The rating of this control spring determines the pressure adjustment range of the regulator. General purpose regulators are available in relieving or non-relieving types. Relieving regulators can be adjusted from a high pressure to a low pressure. Even in a dead end situation, relieving regulators will allow the excess downstream pressure to be exhausted. This causes a loud hissing sound which is perfectly normal. Non- relieving regulators when similarly adjusted will not allow the downstream pressure to escape. The trapped air will need to be released in some other way, e.g. by operating a downstream valve.

Downstream equipment flow and pressure requirements must be determined to properly size the correct regulator for the application. Manufacturers offer flow characteristics charts on their products to help chose the correct regulator.

A lubricator adds controlled quantities of oil into a compressed air system to reduce the friction of moving components.

Most air tools, cylinders, valves, air motors, and other air driven equipment require lubrication to extend their useful life. The use of an airline lubricator solves the problems of too much or too little lubrication that arise with conventional lubrication methods such as a grease gun or oil. Once the lubricator is adjusted, an accurately metered quantity of lubricant is supplied to the air operated equipment and the only maintenance required is a periodic refill of the lubricator reservoir. Adding lubrication to a system also “washes away” compressor oils that travel through the system in vapor form. Mineral oils added to the system prevent synthetic compressor oil build-up on system components. When lubricators are not used in a system, a coalescing filter should be installed to remove compressor oil aerosols.

There are two types of airline lubricator: Oil-Fog for heavy applications such as single tools, cylinders and valves and Micro-Fog for multiple applications, several cylinders or valves. In oil-fog lubricators, all the oil droplets seen in the sight dome are added directly into the air flow. This results in relatively large oil droplets passing downstream. In micro-fog lubricators, the oil droplets seen in the sight dome are atomized and collected in the area above the oil in the bowl. The smaller, lighter particles are drawn into the air flow and pass downstream. As a result, typically only 10% of the oil seen as drops in the sight dome is passed downstream.

Lubricators are sized by downstream flow requirements. An analysis of air flow use must be made. After determining how much air flow is needed, a lubricator can be chosen. Manufacturers’ curves will be similar to the one shown.

Should I use an FLR when shot blasting or paint spraying? If no, what should I be using to remove moisture from the airline? I keep getting water into my shot blast gun which stops it working.

thanks

If possible, a dryer should be incorporated into your blast air. Depending on your required flow rate, there are some point of use desiccant dryers that along with good filtration will reduce the moisture to a more acceptable level. Companies that offer industrial air compressors will be able to help.

What viscosity oil and weight should I use in my small lubricator

Can I use FRL to maintain N2 blanketing at 0.2 kg/cm2G pressure in storage tank ?