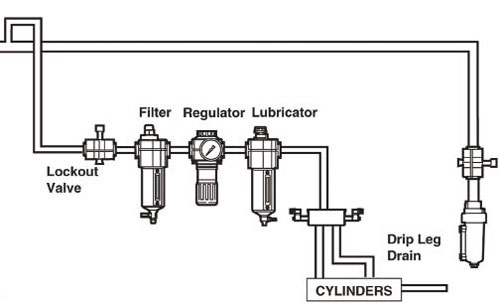

Filter regulator lubricators (FRLs) take what can be hot, dirty and wet air from a compressor and make it safe for use throughout the other parts of a compressed air system, which can be sensitive to contamination.

First, the air-line filter traps solid particles like dust, dirt and rust while separating water and oil. Removing these contaminants from a pneumatic system helps protect the other down-stream components like the regulator, lubricator, directional control valves and cylinders.

The regulator then reduces and controls the fluid pressure in the compressed air system. Theoretically, output pressure from the regulator is constant regardless of input pressure variances. The reality

is that small input pressure differences do cause minor changes in output pressure.

Next the lubricator adds a specified amount of oil into the compressed air system. Once a lubricator is calibrated for the proper amount of lubricant, the only maintenance requirement is refilling the lubricator reservoir.

Some combination of filter, regulator and lubricator (or a three-piece unit) can be found on nearly all air tools, pneumatic systems and air powered equipment. Clean, properly lubricated air at the right pressure is essential to the working life of a compressed air system.

Leave a Reply