A power utility had a 100-psi station service compressed air system that was used infrequently for maintenance. Two 50-hp water-cooled compressors were installed to maintain system pressure during the high flows, but these were overkill for normal times when the compressed air flow was only about 10 cfm. To reduce the number of starts and the operating hours on the big compressors, a small pony compressor was installed to feed the low load while the other compressors remained on standby.

The plant workers noticed that the system was quite wet, causing water to pool low spots within the piping. This caused corrosion, and at high flows, there was significant rust present in the air clogging air tools.

An auditor was called in to look at the system and found that the system had no air dryer, but because the main compressor cooling water was always very cold (45° F), the dewpoint of the air produced by the 50-hp compressors was always below ambient. The pony compressor, a 5-hp two-stage reciprocating compressor, however, was an air-cooled unit with a very poor cooling system. The only discharge cooling provided on this unit was a coil of finned copper tubing ventilated by a fan on the compressor pulley. The discharge temperature of this compressors was over 250° F, and it discharged straight into the main system.

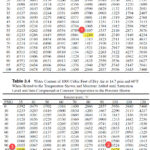

The auditor showed the plant Maintenance Foreman a table of water content values at various temperatures taken from the Compressed Air and Gas Handbook, Chapter 3. The table showed that even at 120° F,A s the water content of the hot compressed air produced by the small compressor contained 10 times the air that 50° F compressed air contained. Allowing uncooled compressed air to enter their system was causing the identified moisture issues.

The plant plans to add a water-cooled aftercooler and separator to the small compressor output, this will reduce the dew point of the air below ambient and eliminate the free water problem.

Leave a Reply