A large industrial company was having problems with its air quality. Water was appearing as if at random at one of its most critical processes, causing instrumentation failures and contamination of the product. This issue was difficult to understand because it looked like the refrigerated air dryer was working fine — and dewpoint looked good — but there was still water forming. After dealing with this problem for many months, the company finally called in an expert auditor to assist in figuring out what was happening.

The auditor placed data logging instruments on all the compressors, and measured pressure points, flow, temperature, and dewpoint. His instruments quickly confirmed that there was indeed a problem with air, quality despite the “good’ reading on the air dryer. Interestingly, this problem appeared when one specific compressor ran.

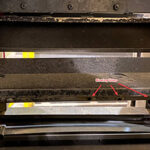

Inspection of the compressor revealed an interesteing problem. The electric water separator condensate drain was missing its electric solenoid — and worse, the shutoff valve was turned off.

Further investigation revealed that the compressor was recently serviced to change the main drive motor. To gain access to the motor, the drain solenoid was removed, but the service personnel had forgotten to reinstall it. This compressor, when running at full load on hot summer days, produces about 100 gallons of condensate per day, all of which was passing into the air dryer, and then down into the plant. The condensate drain on the air dryer was also found faulty due to a restriction within a strainer; only a trickle of water was expelled at every timer drain cycle.

The auditor explained that the reading on a refrigerated air dryer is not really dewpoint, it is the temperature at the coolest point within the dryer. If the moisture is not removed from within the dryer, the water simply passes through, even though internal dryer temperatures remain normal. Hence the reason for downstream contamination.

After placing things back to normal, and a bit of service, this problem was resolved.

Leave a Reply