By Justin Fluegel, Contributor

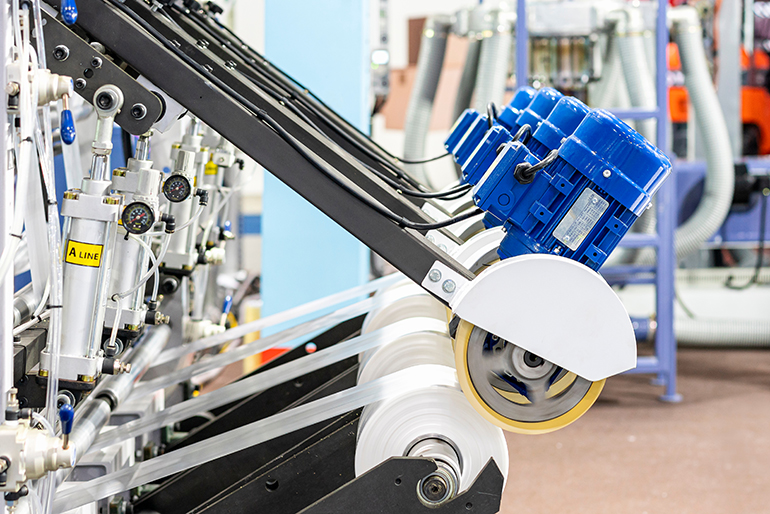

Flow in a fluid power system is synonymous with the velocity of an actuator. Electro-pneumatic flow control valves are used in applications where it is important to control the revolutions per minute of a pneumatic motor or speed of the linear actuator in machinery, such as this plastic roll machine.

Both require feedback information to the controller to regulate the mass flow. For a linear speed control, such as speed of a pneumatic cylinder, a linear variable displacement transducer (LVDT) allows the controller to have the velocity of the cylinder and adjust the mass flow to it to directly reduce or increase the velocity of the cylinder. In a rotational control scenario, such as with a pneumatic motor, a rotary encoder can provide the controller with angular speed of the shaft. This feedback allows the electropneumatic flow controller to adjust the speed to meet system requirements.

Outside of a pneumatic system on a machine, electropneumatic flow controllers can be used to control other functions in processes and machinery. These valves can be found in lasers, paint lines, and liquid spray coating applications. Injection molding either with metal or plastics benefit from using electropneumatic flow control valves to measure amount of material being injected into the mold or quench temperature control by controlling volume of coolant in the system.

Medical device manufacturers use proportional flow control valves to assist with regulating the amount of oxygen a patient receives when on a ventilator. Another medical device using pneumatic flow control valves is anesthesia machines, to mix the medical gases into the air to anesthetize patients prior to surgery.

Opportunities for these valves continues to grow. As demand for precision volumes and speeds in movement of gases improves, and the speed which controllers can process information, these valves will become more common place in systems.

Leave a Reply