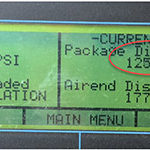

A compressed air auditor placed data loggers on a 100 psi system, measuring pressure, power and flow. He downloaded the data and started scanning through it only to find a surprise. Instead of finding a system running between its 90 to 100 psi setpoint, the system, during low load times reached as high as 150 psi.

The air compressor was supposed to unload at 100 psi when its inlet modulation control valve could no longer keep the pressure within the set band, but internal problems within the compressor enclosure prevented the unit from unloading. It continued to produce about 180 cfm of compressed air even though the actual load was quite a bit less during night shift.

A compressed air system is like a bank account — if you continue to add more than you take out, the balance increases. In this case, the pressure rose slowly to a point where the receiver pressure relief valves released, limiting the pressure to under the maximum rating of the storage receivers. A dangerous situation!

Compressed air operators should continue to keep an eye out for improper compressor operation that may cause safety concerns. Compressors don’t always unload correctly and can cause pressures to rise to undesirable levels. Proper maintenance and understanding how compressors work is key to preventing major failures.

Leave a Reply