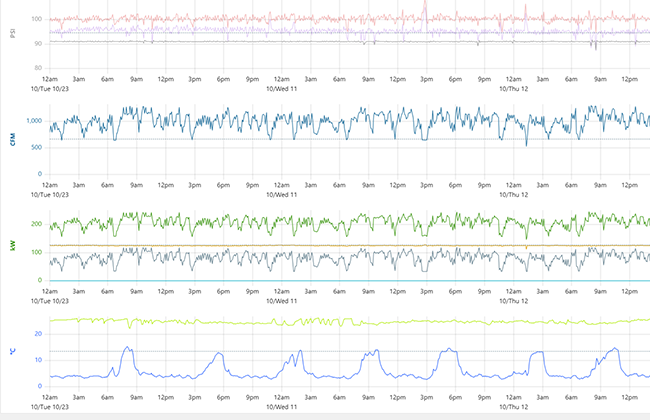

A compressed air auditor was hired to have a close look at the main compressed air system at a farm implement manufacturing plant. Data collection instruments were placed on the system to measure pressure, flow, and power. The auditor also placed a dewpoint meter at the discharge of the compressor room, after the main air dryer, and a temperature monitor to measure the cooling air.

When looking at the profile, the auditor immediately discovered bumps in the time-based dewpoint readings. High readings were being encountered about two times per day for some reason (Fig. 1). The bumps did not coincide with any high flow events or compressor cooling air overheating, so this was a “head scratcher” sort of problem.

A detailed investigation revealed that the dryer drain was failing and operating intermittently. The drain had an alarm light blinking showing it had a fault, but maintenance personnel did not notice this item.

These dewpoint excursions had the real possibility of causing production defects because the dewpoint was occasionally reaching near ambient temperatures. Once the “pressure dewpoint” exceeds the ambient temperature, water will condense out of the compressed air and form free water that can travel downstream into critical tools and equipment.

These dewpoint excursions had the real possibility of causing production defects because the dewpoint was occasionally reaching near ambient temperatures. Once the “pressure dewpoint” exceeds the ambient temperature, water will condense out of the compressed air and form free water that can travel downstream into critical tools and equipment.

This location had two powder painting lines that were installed to ensure a high quality finish on the final product. Water contamination could cause paint defects requiring expensive rework.

A key recommendation at this site is regular testing of condensate drains but also the installation of permanent dewpoint monitoring, with alarm function, to detect when problems occur. The dew point indicator on a refrigerated air dryer should not be relied upon to detect drain failures, the reading is simply the temperature inside the dryer, not the actual dewpoint.

When measuring compressed air systems, it is always important to measure parameters like dewpoint.

Verification of correct drain operation is important, as the article states. Too often it is ignored as just another shop noise.

The solution I came up with at one business was to set the drain operation exactly at quitting time, so that all of the hourly people would pay attention to it, and if it was not heard the foreman was always notified right away. That was probably the cheapest problem solution I ever created, as well as being welcomed and appreciated.

The daily blow-down of condensate was important, but it was often unnoticed among all of the shop noise, and so not missed. This was a problem.

Then I suggested doing the valve opening every day at exactly quitting time.

Not only was the whole place quieter, but soon all of the workers recognized it as the quitting time notification.

The result was that if ever it failed the shop foreman was notified almost immediately and very reliably.

Never another missed drain cycle.

This was probably the cheapest and simplest problem solution ever.