Compressed air is useful for very many important tasks in facilities. However, due to the high cost of producing it, there are some end uses that are very wasteful. Air conditioning and ventilation is one such inappropriate end use. In a recent survey, a compressed air auditor found a surprisingly unique waste of compressed air […]

Components

Compressed air fail: Corrupted VSD settings

When the equipment is new and set up correctly, the coordination of VSD air compressors with fixed speed units is quite easy — if the number of compressors in the mix is four or less. Typically, what should happen is the VSD compressor maintains trim position with all combinations of fixed speed compressors providing base […]

Compressed air fail: Hidden filter

A compressed air audit at a metal parts painting plant yielded some puzzling results. Pressure loggers were placed at the compressor discharge and in the plant, but the readings were showing an unexpected and significant pressure drop between the instruments. Visual checks showed that the only thing between the loggers was an air dryer with […]

High-precision pressure regulator offers stability under variable conditions

ControlAir LLC today announced the introduction of the new Type 410 high precision pressure regulator. The Type 410 provides a high level of regulation accuracy and repeatability during variable operating conditions. Designed with precision and reliability in mind, the Type 410 serves as a cost-effective yet highly efficient solution for controlling industrial processes. Despite its […]

Series 5000 operator system for higher pressures and increased flow

Spartan Scientific announces the launch of its Series 5000 Operator System. Designed to meet the demands of applications requiring higher pressures and increased flow rates, the Series 5000 fills a void in the market for reliable, high-performance solenoid solutions. Featuring a range of orifice sizes from 0.6 to 4.0 mm, and available in both 2-way […]

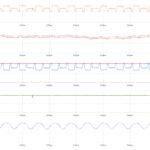

Compressed air fail: Dryer balance

A compressed air auditor was monitoring a system in a plant that produces plastic film. Part of the measurement involved analyzing the flow from the compressor room and the dewpoint of the compressed air. When examining the data, a strange pattern developed on the flow and dewpoint profiles (Fig. 1). We can see the output […]

Free pneumatic positioning optimizes gripping

Pneumatic grippers are revered for being an economical, easy-to-maintain solution with high force density. However, force control and precision can prove challenging, especially when handling delicate parts and parts of different sizes. Sensory feedback is essential in such applications to measure parameters such as the force applied, object position, and speed. Position sensing is especially […]

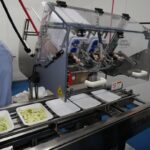

One Cajun beef, please, but hold the air compressor oil

No one wants air compressor oil contaminating production. And in food processing applications, quality and safety are essential. E2M Kitchen, a fresh and ready-to-eat meal provider, knows this all too well. The Charlotte-based company significantly evolved its food preparation and packaging process for creating gluten-free, dairy-free, and preservative-free meals. Every tool used in its production […]

Distributed electro-pneumatics streamline equipment designs

Machinery builders and OEMs save space and improve functionality by applying electro-pneumatic I/O and solenoid systems throughout their equipment. By: Chip McDaniel, AutomationDirect For machine builders and original equipment manufacturers (OEMs) alike, there is an increasing push to deliver smarter, more modular, and physically compact systems. Among the many design choices required to make this […]

High resolution proportional regulators for sensitive applications

Pressure regulation applications that require sensitive, high-resolution performance have found success with the Proportion-Air QPV series electro-pneumatic proportional pressure regulator. The QPV line boasts accuracy of up to ±0.2% and resolution of ±0.005%, regulating pressures up to 150 psig or equivalent. Calibration of ranges as low as 0-2 inches of water column are possible. These […]