By Ron Marshall You may have noticed some email signatures displaying the Certified CCASS symbol — and have become curious as to how that’s earned. Anyone, if properly prepared, can become certified by writing and passing an exam. The ease in preparing for the CAGI (Compressed Air and Gas Institute) Certified Compressed Air System Specialist […]

Air Preparation

Compressed air fail: Dryer balance

A compressed air auditor was monitoring a system in a plant that produces plastic film. Part of the measurement involved analyzing the flow from the compressor room and the dewpoint of the compressed air. When examining the data, a strange pattern developed on the flow and dewpoint profiles (Fig. 1). We can see the output […]

Compressed air fail: Unexpected water

It’s always frustrating to find water in a compressed air system, and especially so in locations where the air is supposed to be dry. During a recent compressed air audit, a survey of the piping found that poor dewpoints were being experienced in the system. Investigation found that significant amounts of free water mixed with […]

Compressed air fail: Extra heat

Most of the energy that goes into an air compressor comes out as heat, so it is always a good idea to direct the hot air produced to a location that needs heat — like into a plant in the winter season. The compressor in the photograph has a specially designed heat recovery system that […]

Compressed air fail: Bad water

Water-cooled compressors can have an advantage in locations where the ambient conditions are hot — and therefore using air cooled compressors would result in discharge temperatures that exceed the capacity of the air-drying systems. Overloading air dryers could result in free water entering the plant piping system. This would cause contamination of connected machines and […]

Compressed air fail: A rat’s nest of wiring

An air compressor at a metal processing plant had a troubled life. It started out as a VSD controlled machine, but a fire damaged the controls. Because of this, a new VSD was installed. It didn’t match the old drive, so wiring was altered to accommodate. Next, the drive failed due to dust contamination and […]

Compressed air fail: Quadruple dry

A metal processing company had a laser cutter installed in its manufacturing plant to produce accurately fashioned pieces from metal sheets. This machine requires compressed air that is dried to about 35° F for general use but requires a small amount of air to keep the beam path clean —this avoids contaminating the expensive positioning […]

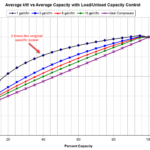

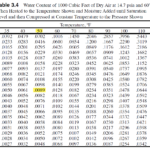

What is a lubricated compressor banana curve?

If you are carefully selecting your new compressors by looking at Compressed Air & Gas (CAGI) data sheets, you should be commended. Use of these sheets are a great way to compare compressor energy and flow characteristics between brands of compressors. In this way, you can choose the most efficient machine for your use and […]

Compressed air fail: A small compressor issue

A power utility had a 100-psi station service compressed air system that was used infrequently for maintenance. Two 50-hp water-cooled compressors were installed to maintain system pressure during the high flows, but these were overkill for normal times when the compressed air flow was only about 10 cfm. To reduce the number of starts and […]

Bringing real-world pneumatic experiences to college students

As the fall semester for Purdue Polytechnic Institute rolled to a close earlier in December, students in the school’s capstone programs reached the half-way point on their efforts. Proportion-Air is sponsoring two capstone teams this school year. Both teams visited the company’s Indiana manufacturing facility in the fall semester, learning about manufacturing processes and asking […]