If you are carefully selecting your new compressors by looking at Compressed Air & Gas (CAGI) data sheets, you should be commended. Use of these sheets are a great way to compare compressor energy and flow characteristics between brands of compressors. In this way, you can choose the most efficient machine for your use and save energy costs. Compressor energy costs can make up more than 80% of the 10-year life cycle costs of an air compressor.

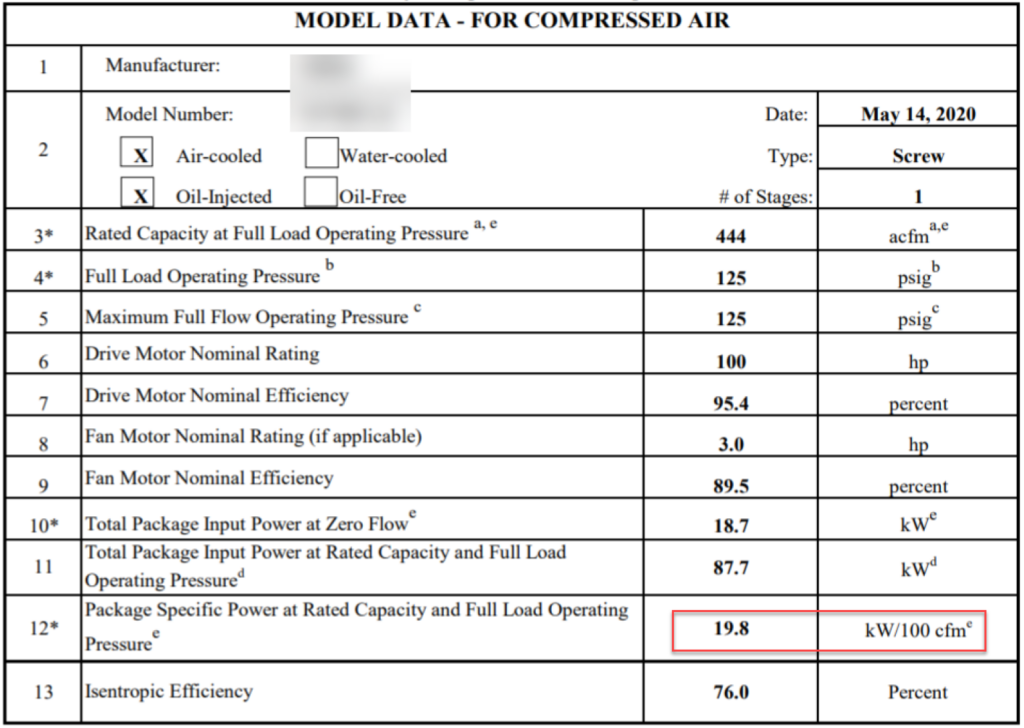

These CAGI sheets are available for any compressor made by a manufacturer participating in CAGI’s third party verification program that tests and maintains honesty in the data presented to customers. Fig. 1 shows an example.

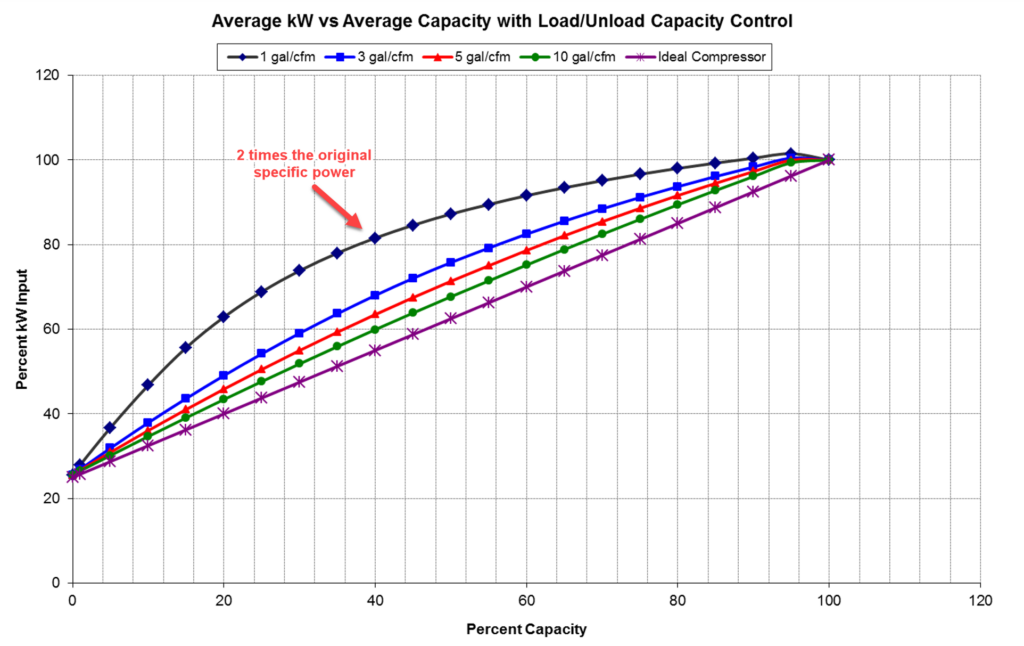

But one downfall in using these sheets for fixed cycle compressors is that there is no data presented for part-load conditions. The efficiency of any compressor operating in load/unload mode changes depending on compressor loading, pressure band, and compressor blowdown time. These general characteristics are plotted on Fig. 2.

We can see from the chart (assuming 10 psi pressure band and 40 sec blowdown time) the compressor at full flow will maintain rated flow and power, but at lighter loads the drop in power with reduction in average flow is not linear — especially if the available receiver size is not large enough.

Consider on the chart, with 1 gal per cfm storage volume, the 40% flow position has more than double the input power per unit output than at full rated flow. This shows that not only should the CAGI sheets be examined when installing a new compressor, but also the available storage volume. An increase in volume for this compressor to 5 gallons per cfm would reduce the power consumption at 40% flow by 22%, savings significant over the lifetime energy costs.

It pays to check CAGI sheets and storage volumes!

Leave a Reply