Diamond cutting is a task for human beings. The cutting must be carried out by a perfectly trained specialist, because — no matter how flawless the gemstones may be — an incorrectly placed cut will ruin everything. Even with perfect color and purity, the wrong cut can significantly reduce the value, which is why good grinders are considered artists in the industry.

The sorting of the stones according to size, however, is done by machines. Much depends on them, too: the sorting process has to be very fast, yet there must not be any scratches. A sorting system with fast-switching valves from Festo manages to sort up to 10,000 diamonds per hour according to size without scratches.

Once the cutting of the precious stones is finished, much more speed is required. For sale, the stones must be quickly sorted according to size, traditionally using a sieve. Although the process is quick, it has some disadvantages: it is very imprecise and stones regularly get stuck in the sieve. There is also the danger of damaging the diamonds.

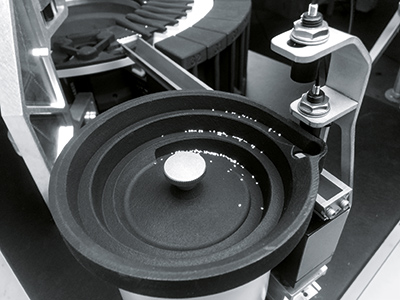

A more gentle alternative is optical straining, where a camera determines the size of the stones. For this purpose, a vibrating spiral conveyor — a special conveying device for dusty to coarse-grained bulk materials — first transports the diamonds one after the other onto a rotating, round glass plate and carefully turns them onto their flat side.

A vibrating spiral conveyor transports diamonds to the optical sieve and aligns them on their flat side. In this way, the conveyor prevents the stones from being damaged during tipping.

A vision system with a camera is mounted above the glass plate. A photoelectric cell detects each new stone on the glass plate and triggers the camera. The vision system counts the pixels on the captured image to determine how large the gemstone is.

For the actual sorting of the gemstones, pneumatic valves are arranged in a circle under the rotary disk on which the diamonds are placed. Containers for the different stone sizes are positioned around the glass plate. As soon as a diamond passes the container corresponding to its size, the valves emit a compressed-air pulse and push it into it.

As soon as a stone has reached the ejection point corresponding to its size, a compressed-air pulse pushes it out of the valve into the corresponding container.

To ensure that the compressed-air pulse is as fast and precise as possible, fast-switching valves are used. These valves contain a magnet, into which a relatively high current is introduced for a very short time. This builds up the magnetic forces very quickly that attract the valve body, and the valve opens. The current is then immediately turned down to a minimum and finally turned off, causing the valve to close again.

Quickly reducing the current makes very high cycle rates possible — in other words a constant opening and closing of the valve, without the magnet overheating and the valve failing. In addition, it switches very smoothly in every cycle. In total, the time per cycle is no more than 3 msec and around three stones per second are pushed into the appropriate container. With such fast sorting, the grinder can take a little more time for a perfect result.

Festo

festo.de/katalog/mhe2

Leave a Reply