A little button press can make a big difference. The compressor in the photo was running in a control mode called online/offline (aka load/unload) for the first bit of its service life but now has been changed to a mode called modulation.

The reason for the change, as found by a compressed air system auditor, was low pressure. When running in online/offline mode, this 100 psi rated compressor was limited to operating between 90 psi and 100 psi, but this caused pressure problems within the plant. Selecting modulation mode allowed the compressor to operate between 100 psi and 110 psi, a better pressure level for the production machinery, however, it came at a large cost.

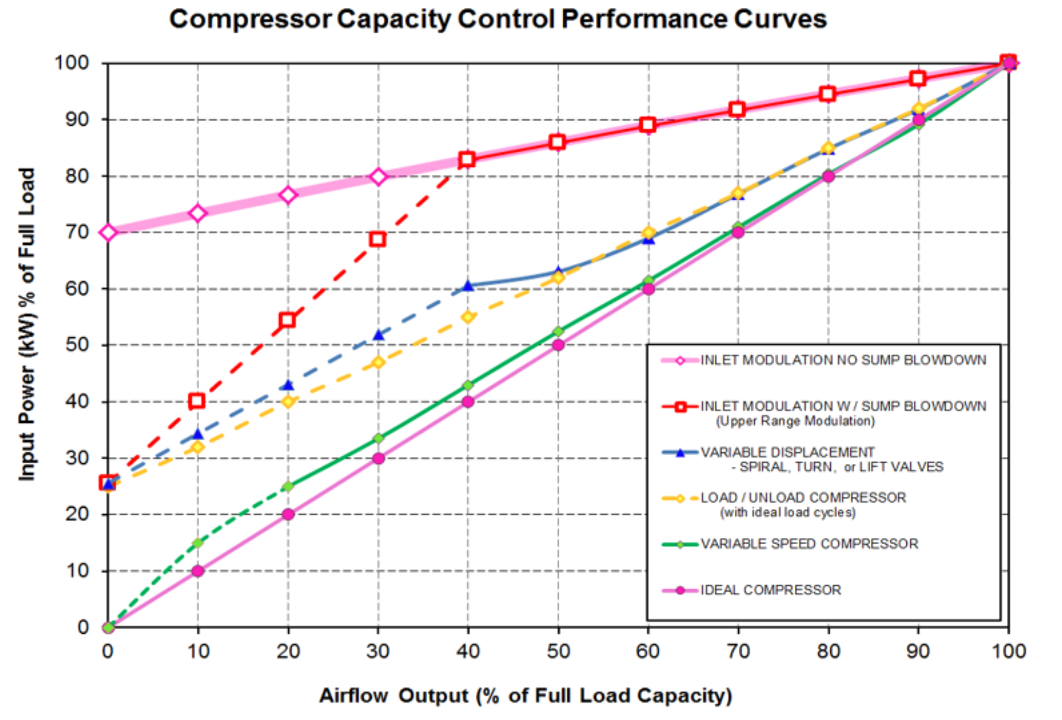

Modulation mode is the least efficient operating mode for a partly loaded compressor. Selecting this mode made the compressor consume 90% of its full load power even though it was only producing 60% of its capacity. The extra pressure it was producing also caused more compressed air to flow in unregulated uses in the plant. The push of the button that changed the mode of this 250-hp compressor increased the power consumption by 20%, costing an extra $6,000 in energy costs per year.

Further investigation was done on this system and found that the main piping was only 3-in. size, which was undersized for the peak flow, causing excessive pressure drop in the far reaches of the plant. This was corrected by looping the piping, allowing the compressor mode to be changed back to normal. The customer is now investigating compressors that would allow variable frequency mode of operation which will likely save an additional 15%.

Leave a Reply