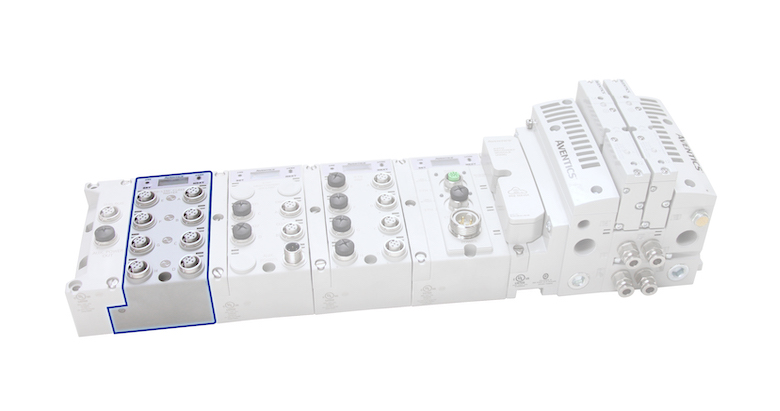

Emerson has introduced a new Class A, IO-Link master that provides customers with a cost-effective solution for smart and analog sensor connectivity on the Aventics Series G3 Fieldbus platform. The G3 IO-Link Master is suitable for machine architectures with many sensors and pneumatic valves, and where it’s important to have reliable digital data communication between field devices, such as sensors and the machine controller. Application areas include automotive, tire manufacturing, food and beverage, packaging, and metalworking.

IO-Link is an internationally standardized I/O technology (IEC 61131-9) for communication at the sensor/actuator level in machine control. During replacement, IO-Link devices can identify and configure themselves automatically, saving maintenance time. The IO-Link master provides pneumatic valve control through direct digital data communication with the machine controller. It offers event-based and I/O mapped diagnostics — both important predictive maintenance requirements for Industry 4.0 and Industrial Internet of Things (IIoT) applications.

By adding the IO-Link capabilities to our valve systems, our customers can include multiple IO-Link masters on only one G3 Fieldbus platform, saving hardware costs, thus enabling our customers to be future-proof and positioned for Industry 4.0/IIoT application requirements.

Customers can cut costs by reducing the number of communication nodes. G3 IO-Link master is optimized for sensor-rich applications with eight Class A ports per module to support multiple IO-Link smart and standard analog sensors. The IO-Link master can be distributed up to 30 m away from G3. Together with the 20-m IO-Link cable length maximum, the sensors can be located up to 50 m in total from the G3 Fieldbus platform. As a result, material cost is reduced, and machines are more streamlined because fewer cables are required.

The IO-Link Master offers a complete Emerson solution. Customers can experience the benefits of integrating IIoT into their systems by connecting to the IO-Link-capable Series AV03/AV05 and 500 valve systems, Series EV12 and EV18 electropneumatic pressure regulators, Series 617 Sentronic LP and Series 614 Sentronic PLUS proportional valves, Series ECD-IV and ECD-LV intelligent compact vacuum ejectors, Series SM6-AL distance measuring sensors, Series ST4-2P magnetic proximity sensors, Series PE5 and PE7 pressure sensors, and Series AF2 flow sensors. In addition, Class B IO-Link solutions can be supported with an optional T-adapter.

The G3 is the only fieldbus electronics platform for pneumatic valve systems that contains a graphical display used for configuration, commissioning, and diagnostics. It offers improvements in performance and reduces maintenance for original equipment manufacturers (OEMs) and end- users alike. The G3 IO-Link Master can also be configurable with the G3 web server. With easy access to connections, the electronic platform is simple to assemble, install, commission, and maintain. G3’s functionality allows programmable logic controllers to efficiently turn valves on and off, and to channel I/O data from sensors, lights, relays, individual valves, or other I/O devices via various industrial networks.

Further benefits include compatibility with the full G3 range of valve interfaces, including Series 501, 502, 503 (ISO15407-2), 2035, 2002, 2005, 2012 and 511, 512, 513 (ISO 5599-2). The G3 IO-Link Master supports the widely used protocols EtherNet/IP DLR and Profinet. Additional protocols are available upon request.

For more information, visit https://www.emerson.com/en-us/catalog/aventics-g3.

Leave a Reply