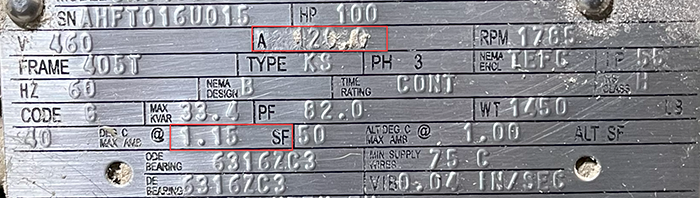

Quite often, people are surprised when they measure an air compressor and find the motor is consuming more than rated amps. One of the unfortunate things about the industry is that it is common to see motors are being stretched into the “service factor” in order to get more cfm out of a given compressor size. Often, this type of operation has little effect because the compressors will not be running at full load and worst-case ambient temperatures — so therefore aren’t pulling normal amps. Other times, it is a problem that can cause motor burnout. You can tell the rated amps and the service factor of an electric motor by looking at the nameplate (Fig. 1).

An electric motor’s service factor (SF) is a multiplier that indicates how much over its rated power an electric motor can handle without overheating or suffering a reduction in its lifespan. The service factor is provided by the motor’s manufacturer and is typically found on the motor’s nameplate.

Why is this done? Well, you be the judge. If you were shopping for a 100-hp nominal rated air compressor, which would you choose; one with 380-cfm output or one with 440-cfm output? If we dig further into the actual power draw, we will find the latter compressor will be running well into the motor service factor.

Here are some key points about motor service factor:

- Overload Capacity: It indicates the percentage of overload the motor can sustain for short periodswithout damage. For example, a motor with a 1.0 hp rating and a service factor of 1.15 can handle 1.15 hp without overheating.

- Safety Margin: The service factor provides a safety margin beyond the motor’s nominal rating.

- Dependence on Conditions: The ability to use the service factor can depend on operating conditions, such as the voltage supply, frequency, and ambient temperature.

- Not for Continuous Use: It’s important to note that the service factor is not intended for continuous use — but can be used to cope with intermittent or temporary load increases.

- Impact on Efficiency: Operating a motor continuously above its rated capacity, even within the service factor, can decrease efficiency, increase operating costs, and reduce the motor’s service life.

If in the market for a new air compressor consider the service factor into your questions to the supplier to ensure you are a happy customer in the end.

Leave a Reply