A building products company purchased a compressor with 1,520 cfm capacity to help with the increased load after a plant expansion. Various dryer sizes were available, but one sized at 1,600 cfm was selected, rather than choosing the next size up, to save purchase costs.

Shortly after installation, the production machine operators started complaining about water in their compressed air. A compressed air auditor was called to investigate. The auditor took various temperatures and pressures and found that the plant pressure was operating at 80 psi, the inlet compressed air temperature was 110° F, and the ambient temperature of the room where the compressor was installed was 110° F — due to hot compressor cooling air being blown on the dryer. These temperatures and pressures are not within the normal rating of the dryer, so the dryer was undersized for the conditions.

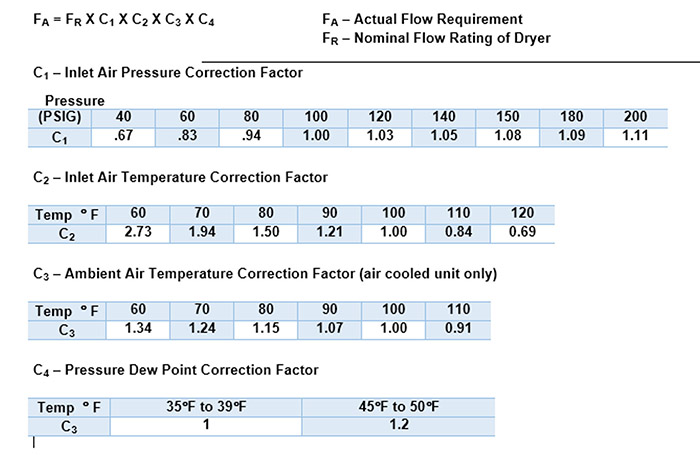

Plant personnel were not aware that air dryers of the type installed must be sized for worst case scenarios using the “Three 100 rule,” which means their existing unit did not have enough capacity to properly dry the air during hot conditions. Using the correction factors in Fig. 1 above, the existing dryer was only rated at 1,600 x 0.94 x 0.84 x 0.91 = 1,150 cfm. The dryer size required here needed to be 40% larger than the compressor full load capacity, or at least 2,100 cfm rated.

The auditor pointed out that managing the room temperature and reducing the compressor discharge temperature could help, if this could be done to reduce the various temperatures in warmer weather.

If you want adequate compressed air quality, even during the hottest and most humid summer days, after a rainstorm, perhaps your worst case scenario, remember the “Three 100 rule” for dryer sizing.

Leave a Reply