By Frances Richards, contributor

Pneumatic cylinders are a clean and cost-effective option for achieving reliable linear motion in many industrial environments. Because they are lighter weight and lower maintenance than their hydraulic and electric counterparts, they are an excellent choice in applications from factory automation and transportation to packaging and life sciences. Two main styles exist: single-acting and double-acting.

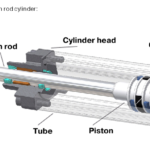

In single-acting pneumatic cylinders, air is supplied through one port to one side of the piston, causing the piston rod to extend in one direction for a task such as lifting an object or pressing one object into another. The other side of the cylinder vents air to the environment. Movement in the opposite direction occurs most often by means of a mechanical spring, which returns the piston rod to its original or base position. Double-acting pneumatic cylinders feature two ports that supply compressed air to both extend and retract the piston rod. Double-acting designs are far more common throughout industry, with an estimated 95% of applications using this cylinder style. However, in certain applications, the single-acting type is the most cost-effective and appropriate solution. Here we will explore where single-acting pneumatic cylinders are a good fit.

Single-acting cylinders are a great choice for applications with space constraints, as these tend to be smaller cylinders than other designs due to their integrated springs that leave less room for compressed air. Analytical equipment, diagnostic instrumentation, bottling machinery, and commercial laundry and kitchen equipment are just a few examples of where these single-acting cylinders are specified. They are typically used in applications where work is performed in one direction. These include tasks such as positioning, marking, clamping, and light assembly.

It is also helpful to consider the advantages and drawbacks of this cylinder style in order to determine where single-acting cylinders are an appropriate option. On the plus side is their compact size, simple design, and reduced valve and tubing costs compared to their double-acting counterparts. Also keep in mind that air consumption is 50% less than that required for an equal sized double-acting cylinder, boosting their efficiency and lowering their operating costs.

Disadvantages are also important to be aware of, to determine if any of these factors is a deal breaker for a particular application. First, the side of the cylinder that houses the return spring is vented to the ambient environment, which could allow ingress of foreign particles and lead to reduced cylinder life. Second, spring operation can become inconsistent and lead to uncertain end-of-stroke positioning over time. In addition, bore size and cylinder stroke are both restricted due to limitations in spring size and available force. Finally, a slight reduction in thrust can be expected due to the opposing spring force. Because of these factors, single-acting pneumatic cylinders have a limited stroke length but are often useful in more compact and slower operations.

Single-acting cylinders are often found in factory automation settings, performing jobs such as materials handling and packaging operations. Here they are used to position parts and tools, helping with tasks such as clamping and punching. They can also be found in specialized pumps and hydraulic rams, assisting with jobs such as lifting heavy items. Pushing, pulling, lifting and lowering are other actions these single-acting cylinders can assist with. Overall, single-acting pneumatic cylinders are highly efficient, simple, durable, and easy to install, making them an excellent choice for reliable linear motion in the right application.

Leave a Reply