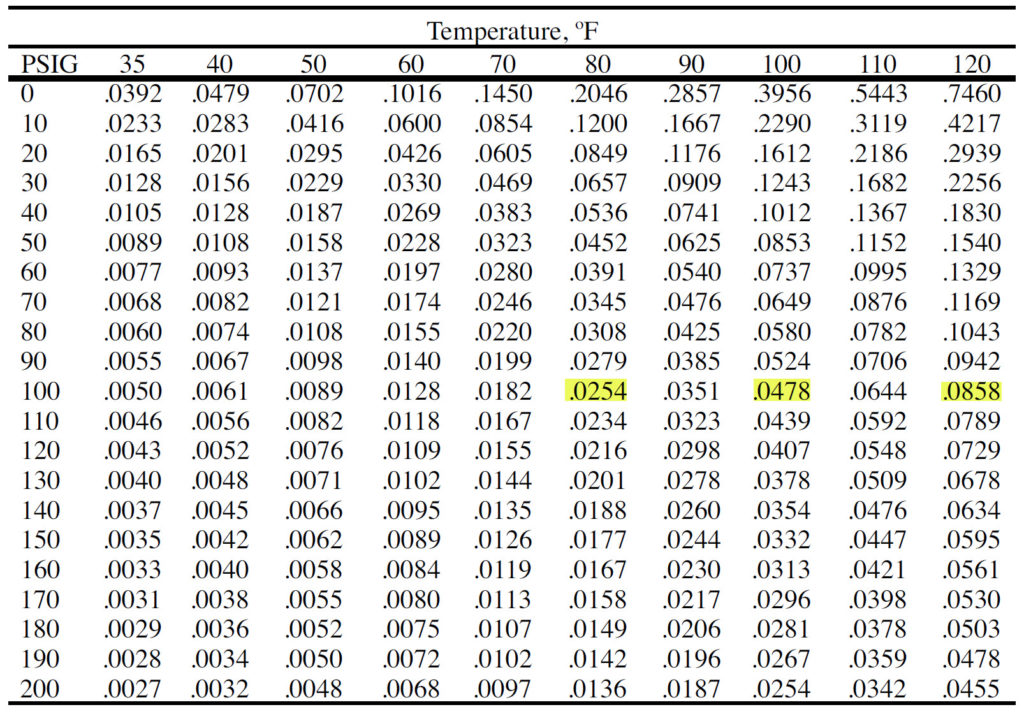

If experiencing troublesome “water in the compressed air” problems, it often helps to understand the moisture carrying capabilities of compressed air. A rule of thumb is often used to help understand the effect of temperature on the water content of saturated compressed air. The rule states: “At 100 psi, every 20° F increase in air temperature roughly doubles the amount of water vapor in the air.” This rule is illustrated by a table of water content (Fig. 1) published in the free-to-download Compressed Air & Gas Institute (CAGI) Handbook, Chapter 3. You can download it here.

Consider a flow of undried 100 psi compressed air at 100° F being produced by an air compressor. If ambient temperature in the plant is 80°, about half the water vapor in the compressed air with condense out as the air cools. If you do the math the amount of water that would drop out would be 0.0224 gallons per 1000 cubic feet. A 100-hp compressor at full load would produce 633,600 cubic feet of compressed air in a single day, so under these conditions about 14 gal of water would be left in the plant piping per day.

And consider an air dryer rated for 100 psi and 100° F inlet temperature. If the inlet temperature is actually 120° due to overheating of the air compressor, then the dryer must process almost 1.8 times its rated amount of water vapor (round this up to 2 times for the rule of thumb). Most dryers can’t process this kind of moisture overload, resulting in water in the compressed air.

It is important to memorize this rule of thumb if you want to keep water away from your system. Keep the compressed air temperatures as low as possible before reaching the air dryers. At every point of temperature reduction there must be a way to remove condensed water, usually a water separator and drain. The amount of water depends on the flow of compressed air and the temperature difference. Design water removal capacity carefully.

Leave a Reply