Contributed by Troy Sanders | National Sales Manager | Fabco-Air

When your operation calls for a pneumatic actuator, you’ll find a wide range of products available from various manufacturers. But because no two applications are alike, you must weigh several considerations before selecting and ordering an actuator. This article will discuss the different cylinder types available with a focus on interchangeable actuators and the corresponding standards that ensure you can replace existing cylinders without difficulty.

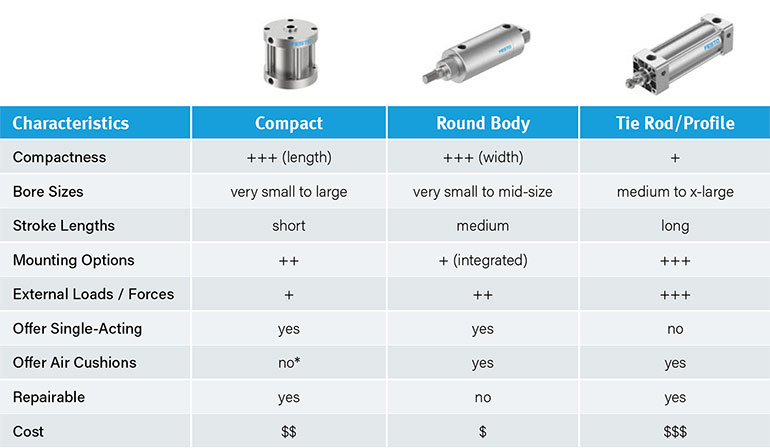

Comparing different types of cylinders

As you begin the selection process, you should have a good idea of the characteristics needed in your pneumatic cylinder. Basic considerations should include the size and mounting options as well as any specific features necessary. Here’s a brief overview of four common cylinder styles:

• Compact cylinders. As the name suggests, compact cylinders are desirable for installations with limited space as well as those with small loads or very small lateral forces acting on the piston rod. Lightweight and repairable compact cylinders have some of the smallest bore sizes available, from 1/4 up to 5-in., and strokes are typically less than 4-in. Compact cylinders have two common styles, including tie rod construction with round or square end caps, and extruded profiles with square bodies. These cylinders are usually mounted via through-holes or tapped threaded holes, or via rear-pivot.

Optional features include a choice of male or female rod threads, single-acting versions, magnetic piston for use with sensors, bumpers to reduce noise, double rods, non-rotating types for maintaining a specific orientation, and seals for harsh environmental conditions.

*Festo ADN Support Air Cushions

• Round body cylinders. Inexpensive cylindrical shaped cylinders are designed with small widths for applications with limited installation space or small to medium load requirements. They are typically used for moving, holding, lifting, and pushing-type use cases, or applications with minimal lateral forces acting on the piston rod. Mounting can be achieved through an integrated front-facing nose thread or a rear pivot 3-in., and strokes can range from less than 10-in. to more than 50-in. They have similar optional features as compact cylinders plus the availability of optional air cushioning to minimize impact forces on internal components. Many round body cylinders are crimped by design and as such, are not repairable.

• Tie rod cylinders. When you need a more durable cylinder, tie rod cylinders can meet the requirements thanks to their large integrated piston rod bushings. Tie rod construction accommodates the large bores — up to 12-in. or larger — that provide thousands of pounds of forces. Strokes can typically range from less than 8-in. to more than 100-in.

Offered with a variety of mounting styles, repairable tie rod cylinders are designed for medium to heavy loads and applications in which medium lateral forces act on the rod. (If an application presents high lateral forces, we recommend an external guide unit.) Their robust construction makes them suitable for harsh environments, and optional seals and scrapers offer additional protection against contamination.

• Profile cylinders. These cylinders offer many of the same features and specifications as tie rod cylinders, but their aluminum profile limits bore sizes to approximately 5-in. Profile cylinder construction offers some advantages, including integrated slots to house a sensor without it protruding from the body, a smooth shape and appearance, as well as lower costs.

Interchangeability standards

Sometimes a machine builder may prefer to replace an actuator with an easier-to-obtain unit or one with more desirable features. To help simplify the transition, the International Organization for Standardization (ISO) and National Fluid Power Association (NFPA) developed standards for cylinder interchangeability. These standards offer the assurance of knowing that a replacement cylinder will be dimensionally compatible across other compliant brands, and machine builders are not bound to one supplier’s products when modifying a machine.

That means customers can obtain replacements that have the same form, fit and function as the original, and they can upgrade equipment faster. These standards typically specify:

- Piston rod-type cylinders

- Standard bore sizes and piston rod diameters

- Standard cylinder strokes

- Piston rod end thread sizes

- All cylinder dimensions that are relevant for customer interfaces, such as length, port thread and mounting dimensions

- Accessory dimensions, in some cases

Not all actuators are created equal. For example, different manufacturers may use different materials in cylinder construction, or they may offer a different scope of standard features or options for their products. Various manufacturers will also have different price points.

You may also encounter de facto industry standards, which typically develop around a product that achieves good market share and is replicated by other manufacturers. Fabco-Air’s Original Pancake cylinder is one such example.

In addition, the company’s varied lineup includes many interchangeable cylinders. Examples include the rugged, high-performance NFPA series available in several versions and 17 mounting styles, and the OEM-NFPA FCQN series of repairable cylinders with OEM pricing. There’s also an ISO 6431 cylinder — the FAQ2R — with a hard- anodized aluminum body. If space is a concern, the Pancake II and stainless-steel F series are also interchangeable.

Strategies for solving application challenges

Here are some common issues you may need to confront when choosing a pneumatic actuator along with considerations to help meet the challenge:

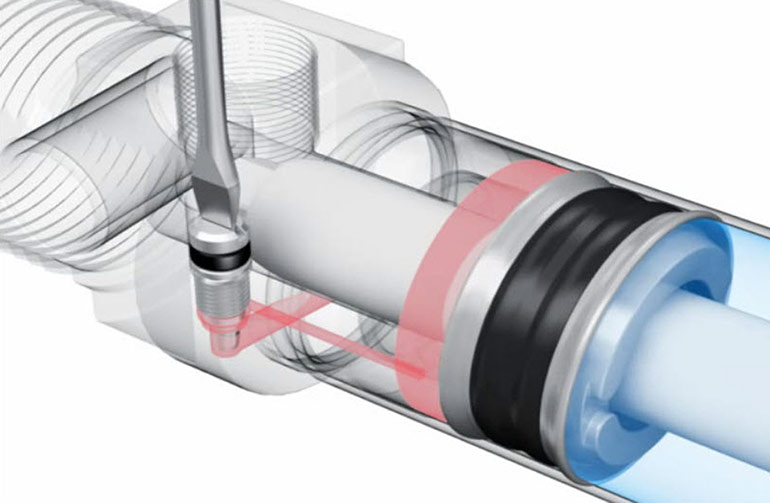

When you need end position cushioning: As a cylinder accelerates across its stroke, it generates energy that, if left undissipated before it reaches its end position, can cause damage to its internal components. Two features can help cushion your cylinder at its end position: elastomer bumpers and air cushions.

For low-energy applications with shorter strokes and slow speeds, elastomer bumpers are integrated onto the piston seal or can be positioned separately in sleeve form next to the piston.

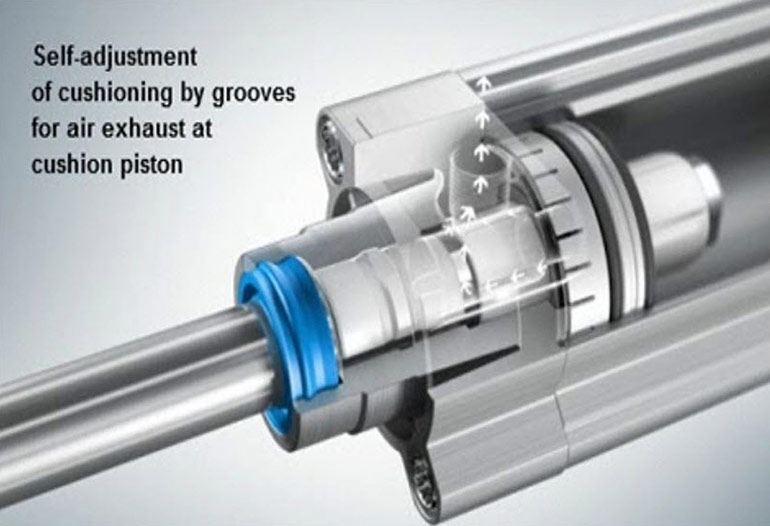

Air cushions provide protection for applications requiring higher energy to support high speeds or a larger mass. They trap air between the cushion seal and the piston, forcing the air through a small exhaust cap, creating a backpressure that slows down the piston before it reaches the end cap. Air cushions may come with a fixed orifice air pathway, but most are manually adjustable using a screwdriver. A third option — self-adjusting air cushions, patented by Festo — forgoes the pathway and sends the air through tapered slots in the cushion spear, creating optimal cushioning even when application conditions change.

When you need maximum force output: Stroke extension creates a higher effective piston surface area, resulting in a higher effective output force, as seen in the following equation:

Output force (F) = operating pressure (P) × the piston surface area (A)

To increase the cylinder’s output force, each of the variables in the equation can be changed. However, these changes present trade-offs:

- Increase the operating pressure. While an obvious first choice, this strategy may cause you to hit compressor strength and pressure rating limits. And using a stronger compressor will require more energy.

- Increase the piston surface area. Consider this approach when you have static operating pressure. However, increasing the piston surface area may call for a heavier, more robust design as well as additional tie rods to support the larger loads. The increased bore size will also cost more and require more installation space.

- Increase the piston surface area by adding more pistons to act on the piston rod. You can, for example, triple your force output by incorporating three pistons on a single rod. This strategy, however, will add length to the cylinder.

When you need to maintain a specific orientation: Some situations do not allow a change in rod orientation between consecutive strokes. If you need to maintain a specific orientation, you have options when specifying your actuator.

If your actuator has a small bore, adding a dual, or twin, rod is an easy choice. Since space will be limited, you may need to forgo secondary features like wipers. A non-circular-shaped rod can also prevent unwanted rotation. Choices include a circular rod with flats throughout the piston rod, hex-shaped rods for single-acting cylinders, or square rods for double-acting cylinders. Non-circular rods can be hard to seal, so you may have leakages. A third option — internal guide pins — is attractive because they do not increase the cylinder’s footprint. Note that the pins are not meant to bear loads, so the rod can only handle a limited amount of torque.

When you need to withstand a harsh environment or ensure food safety: Any time you specify an actuator, you have to consider its operating environment. We recommend you choose the most robust cylinder possible, based on its orientation and operating environment. Consider whether the cylinder will encounter corrosive materials or harsh chemical agents that may contact the rod and rod seal, and select a robust material like stainless steel to resist these elements. Seals and wipers can help prevent exposure.

Food safety and hygienic design should be observed in every aspect of machine design and component selection throughout the food and beverage industry. In food zones, a cylinder can be a breeding ground for bacteria and debris buildup. When specifying a cylinder for a food and beverage environment, follow these best practices:

- Look for a self-draining actuator.

- Avoid corners or dead spaces.

- Avoid fasteners and connectors with threads and crevices.

- Specify corrosion-resistant materials.

- Look for FDA NSF-H1-approved lubricants.

- Make sure the cylinder is well-sealed.

When it comes to materials, the operating environment along with the cylinder type and size will influence your selection. For example, compact or round body cylinders typically offer units made from Delrin or other polymers. These materials are lightweight, cost-effective, and typically resilient to chemicals. Stainless steel is a more robust option, and it is well-suited for acidic applications such as battery production. Stainless steel types 303 and 304 are popular for many applications, while 316 grade stainless steel is desirable for the harshest applications.

Fabco-Air’s F-series cylinder is made of 304 stainless steel and features a 303 stainless steel cylinder rod and high-strength aluminum piston, making it well-suited for light-duty applications in food and beverage or packaging equipment. For space-constrained food equipment, Pancake compact cylinders come in washdown- resistant Delrin and stainless steel versions.

Don’t go it alone

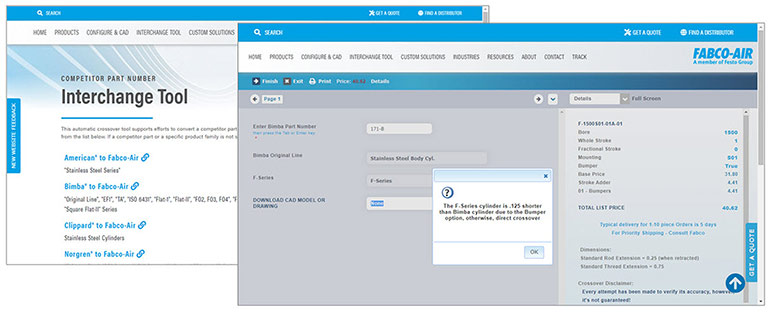

Choosing the right cylinder for your application does not mean you have to go it alone. Assistance is available through online selection tools. For example, Fabco’s online Configure & CAD Tool lets users select a product to configure from the ground up, option by option, or deconstruct a Fabco-Air part they may already have. The website also provides an Interchange Tool for those times when a competitor’s product is not readily available. Simply choose a competitor and enter their part number. You’ll find the Fabco equivalent without the hassle of poring through catalogs and comparing dimensions.

Finally, many manufacturers offer sizing software tools to help save time and avoid mistakes. Tools can range from quick and easy basic pneumatic sizing to more sophisticated simulations.

Make cylinder selection less difficult

Air cylinders come with an abundance of features and options to choose from, and selecting the right unit or choosing the right replacement unit can be difficult. With a proper understanding of the different types of cylinders, interchangeability standards, and the factors to consider when addressing certain objectives, specifying cylinders can be considerably less challenging. Fabco has a wide selection of standard air cylinders and can also provide support and excel at creating custom “specials” for hard-to-satisfy requirements. DW

Fabco-Air

fabco-air.com

Leave a Reply