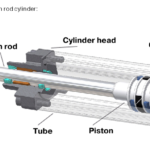

Pneumatics is a fluid power technology similar to hydraulics in that it transmits force through a pressurized medium to create useful work. However, pneumatic technology differs from hydraulics in every critical fashion — compressibility. To be fair, hydraulic oil compresses as well, but only 0.4 percent every thousand psi or so. However, in the simplest explanation, air will compress to half its volume when subjected to double the pressure.

Compressibility is an asset for pneumatic systems, allowing for extremely high acceleration and inherent shock absorption. As compressed air moves from high pressure to one of lower pressure, the expansion accelerates the air. The acceleration occurs at the loads of the actuators to provide the snappy movement pneumatic systems are known for. But, of course, the compressibility of air prevents it from being the first choice for load-holding applications. Still, air-over-oil systems provide a versatile solution when hydraulic power units are unavailable.

Pneumatic systems get their power from a compressor that takes air from atmospheric pressure and reduces it to an eighth or less of its original volume. A compressor’s role is singular, and unless your machine uses every cubic inch of compressor air as exists, the compressed air must be stored. Specialized air tanks called receivers act as a buffer between the compressor and the downstream sub-systems. This buffer stores the compressed air to reduce the compressor’s load and provides extra capacity when overall demand exceeds compressor capacity.

Pneumatic systems operate between 80-120 psi, which depends on the requirements of the loads and actuators in the system. Pneumatic systems compromise the force and speed advantages of higher pressure with the efficiency challenge of high compression. In other words, above 120 psi, the energy required to further pack air into a smaller space is somewhat of a challenge. Higher compression results in more heat, which adds to the system’s complexity as multiple stages and coolers may be required. High-pressure pneumatic systems also experience a higher risk of leaks and failures, sometimes catastrophic.

Actuators cannot use air directly from a compressor or receiver and must first be conditioned to suit each subcircuit or function. Most pneumatic tools, motors, cylinders, effectors and valves prefer clean, dry air with a stable pressure. Therefore, the primary compressor set comes with (or should be optioned with) a pressure regulator set higher than all others in the plant, a dryer large enough to peak demand and a filter to prevent any compressor-generated particles from travelling downstream.

Because each subcircuit may have a separate conditioning requirement, individual branches come fixed with their own conditioning components. Filters, regulators and sometimes lubricators offer tailored control over the air quality for each function. For example, a work cell using pneumatic drills and impact guns require reduced pressure clean air and air tool oil, which combine to improve performance and reliability. On the other hand, an automated paint booth requires a very high volume of clean, dry air with no lubrication, so understanding the requirements of each air system branch prevents costly design mistakes.

Pneumatic applications are diverse, to say the least. Air processes systems, such as sandblasting, are not traditionally a fluid power function since air does not achieve work. Pneumatic actuators are incredibly varied — cylinders, motors, clamps, grippers and rotary actuators offer unique solutions for any designer.

Air cylinders offer quick acceleration for light loads or automated processes, such as packaging equipment, pick and place robots, ejectors or clamps. Air motors offer a high-speed, clean choice to replace light duty electric or hydraulic motors, such as those requiring an inexpensive explosion-proof option.

Grippers used as robot end effectors provide an inexpensive, rapid method to clamp material for manipulation. Manufacturers offer myriad pneumatic clamping solutions, such as two-jaw parallel grippers or a single pneumatic cylinder against a toggle for high clamping force.

Pneumatics offer manufacturers an unmatched combination of performance and economics. Pneumatic actuators and the various pressure, flow and control valves used to control them may be creatively integrated to perform in various industries. For example, food & beverage is served by stainless and aluminum components resistant to washdown while offering finishes resistant to bacteria or fungal growth. Likewise, the medical and pharmaceutical industries benefit from the rapid cycle times provided to robots pressing, punching and ejecting millions of pills or parts.

No matter the industry, pneumatic systems find ways to help. Even using a vacuum to move delicate objects without harm offers another trick in the pneumatic hat. But, as creative engineers and designers know, the possibilities for air-powered machines are limited only to your imagination.

Leave a Reply