An air cylinder’s compressed air use can often be accomplished by reducing pressure or use of other measures. Air cylinders are common devices in pneumatic assemblies and are used to transmit linear force and motion. The basic parts use a piston assembly connected to a rod within a tube. The force produced by the air cylinder rod depends on the area of the piston and the pressure differential acting on the piston.

An air cylinder’s compressed air use can often be accomplished by reducing pressure or use of other measures. Air cylinders are common devices in pneumatic assemblies and are used to transmit linear force and motion. The basic parts use a piston assembly connected to a rod within a tube. The force produced by the air cylinder rod depends on the area of the piston and the pressure differential acting on the piston.

If the piston has an area of 10 square inches and a pressure differential of 100 psi acts on the piston, a force of about 1,000 lb will be transmitted to the rod. But if the required force on the rod is less than 1,000 lb, the cylinder will start to move when the pressure differential is much lower. Lets say only 100 lb of force is required, the piston will only need 10 psi of pressure differential (plus some extra to overcome friction) to start to move. The movement will continue, with about 10 psi pressure differential until the piston hits the stop at the end of the cylinder.

Once the piston reaches the farthest extent of its motion, the pressure on the working side of the cylinder starts to rise as the cylinder fills from the 10 psi required to move the piston, to the system pressure of 100 psi. As the cylinder fills it consumes an amount of air equal to the volume of the cylinder times the number of atmospheres of pressure supplied to the cylinder. In this example, if atmospheric pressure is 14.5 psi the number at 100 psi would be 7.9. So, if the volume of the cylinder is one cubic foot, the amount of air used per stroke would be 7.9 cubic feet. Since the piston had already stopped the amount of air required to pressurize from 10 psi to 100 psi does no work, so most of it is wasted.

When the cylinder returns to its resting position, the other side of the piston is pressurized, the other side of the piston exhausted to atmosphere, and the cycle continues. This return stroke will consume about the same amount of air as the power stroke, less the volume of the rod. It is important to understand that often the return stroke does not do any work so requires much less force.

What does this all mean? Well, it means if you reduce the input pressure to the air cylinder you can reduce the amount of air it consumes.

What does this all mean? Well, it means if you reduce the input pressure to the air cylinder you can reduce the amount of air it consumes.

For every 14.5 psi reduction, the amount of air wasted at the end of the stroke reduces by the volume of the cylinder, in this example one cubic foot. And because the force required for the return stroke might be very low, you may be able to greatly reduce the pressure using a dual pressure strategy, saving even more.

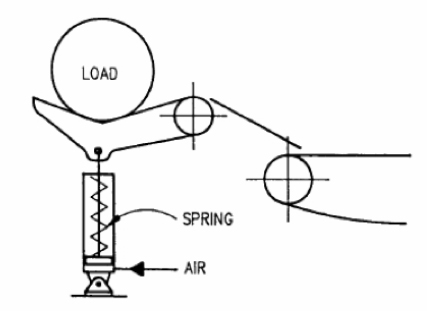

Or why use air at all for the return stroke? Sometimes a spring return or gravity return force will suffice, using no compressed air at all in retracting the piston.

Leave a Reply