At Pack Expo September 23 to 25 at the Las Vegas Convention Center, Festo will be showing pneumatic and electric products compliant with the Food Safety Modernization Act (FSMA) guidelines on safely processing, holding, and packaging food. Visit Festo at Pack Expo Booth LS-6349 to see these technologies in person.

It is vital that compressed air intended for direct contact with food and used at the end of the packaging line is filtered as clean as possible. For this reason, air filtration efficiency of 99.999% is the first line of defense for maintaining food safety.

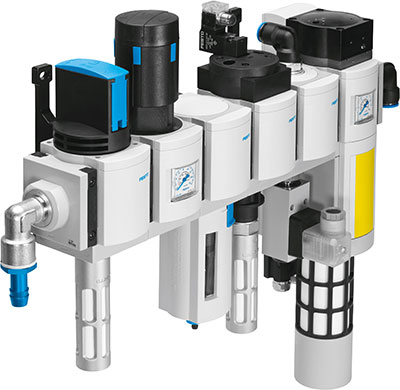

For ensuring that clean air is used on a machine, Festo offers pre-configured MS-Series compressed air preparation units. MS-Series units meet or exceed the Safe Quality Food (SQF) recommendation for 99.999% efficiency and a final filtration stage of 0.01 µm. They deliver air quality of 1:4:2 or better in accordance with the ISO 8573-1:2010 standard.

Clean design valve terminals and actuators

The MPA-C valve terminal is rated IP69K and can be mounted directly on a machine. The MPA-C is designed for harsh washdown environments and its rounded contour ensures cleanability.

Like the MPA-C, the stainless steel CRDSNU cylinder meets current Good Manufacturing Practices (cGMPs) for cleanability. There are no threads on the CRDSNU bearing cap to trap contaminants. Its self-adjusting end-position cushioning system doesn’t contain contaminant susceptible adjusting screws. The actuator also uses NSF-H1 grease and FDA approved seals.

Festo features clean-design fittings and a range of FDA compliant tubing that resists hydrolysis, cracking, and wear in harsh washdown environments.

Many Festo electric actuators demonstrate how the company meets cGMPs outside of the food and splash zones. Electric actuators such as the ELGA feature easy clean wipe-down exteriors. Body profiles prevent buildup of dirt or debris. Units can be pressurized to help prevent ingress of particles.

Festo

www.festo.us

Leave a Reply