When it comes to compressed air, the word “lower” is often used in describing actions to take in implementing energy savings measures. The key is to do certain actions that will lower the electrical bill and the resulting operating and maintenance costs. Here are some common actions:

Pressure — Every 2 psi in lower compressed air pressure reduces the amount of compressor power by 1%. Also, every 1 psi in lower pressure reduced the flow to any unregulated compressed air demands. Very often, compressed air pressure is way higher than is required, why? Well, usually nobody has an answer.

Pressure differential — Very often, the air compressors will be producing adequate pressure, but the devices at the other end of the system are receiving low pressure. Lowering the pressure differential across dryers, filters, piping, regulators, lubricators, hoses, and connectors is usually low cost compared to the energy bill — and can allow you to reduce your compressor pressure.

Leaks — If you want to reduce costs, lower your leakage level! Lower flow reduces the compressor power in a well-controlled system, saving you money by lowering your electrical bill. Implementing a regular leakage detection and repair effort is usually needed; purchase an ultrasonic leak detector and use it.

Temperature — Heat is the enemy of any compressed air system, and the air compressors produce a lot of it. If you want a well-running system, with lower water content in your pipes, you have to keep things cool. Make sure your compressor room is well-ventilated and that your compressor coolers are free of dust and debris. Air that is super-hot entering an air dryer will overwhelm it and cause moisture contamination downstream. Extreme temperatures will kill components like air dryers, causing expensive service calls and required replacement.

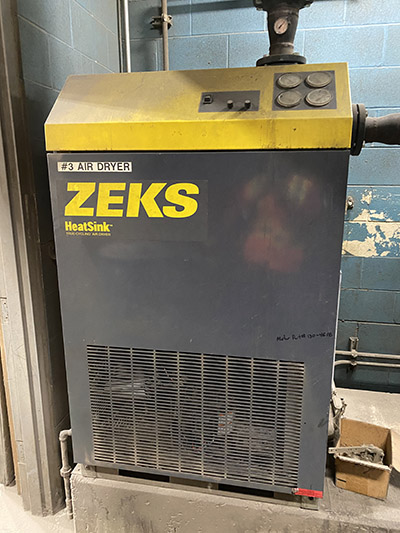

Power/Energy — Selecting compressed air equipment that is of premium efficiency is often a wise decision. The input energy into a standard efficiency air compressor typically represents many times its purchase price over a 10-year period. The air dryer in the picture is an efficient cycling style, meaning that when selected, it saved the customer thousands of dollars in energy over its lifetime. Selection of more efficient equipment, and controlling it well, can significantly lower your energy bill.

How low can you go, it’s up to you to decide.

Leave a Reply