By Ron Marshall

A farm implement manufacturer purchased a variable speed drive compressor several years ago to reduce his compressed air production costs. For many years the compressor performed as expected, taking the plant’s part load while one or two base units provided efficient full flow duty.

A few months ago, there was a change to the system requirements and a desiccant dryer was installed. The dryer and associated filters added some extra pressure loss to the production side of the system, reducing the plant pressure. As a result, the VSD setpoint had to be increased to avoid low pressure problems at pressure sensitive torque tools.

After the change, a compressed air auditor monitored the system. He found some unexpected results — the VSD was turning off during lighter non-production loads and the base unit was running in a mode called modulation. Instead of the system running at a specific power of 18 kW per 100 cfm, the total system level was at an inefficient level of 33 kW per 100 cfm. The auditor diagnosed the problem as improper pressure coordination.

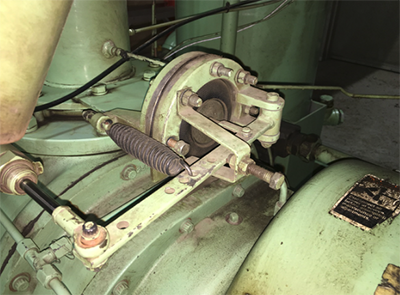

The coordination problem was caused when the VSD target pressure was adjusted, the VSD target setpoint was increased but the base compressors remained at the previous settings. The fix is a simple twist of the wrist, turning the modulation control screw in one quarter of a turn so the base unit stays out of modulation mode.

So many systems like this suffer from settings creep — alteration of the actual settings from the previous correctly coordinated setpoints. Properly adjusting the setpoints will yield about 45% in savings, worth about $30,000 per year. Not bad for a quarter turn with a screwdriver! This proves the value of regularly baselining your system to ensure proper operation.

Leave a Reply