An electronics parts manufacturer had a maddening water problem. Every day around Noon, its air system pipes started emitting free water at their most important end uses.

This water came mixed with compressor lubricant and the dust ingested by the compressor intake. With the addition of pipe rust and scale — which formed due to water corroding the inside of the steel pipes — this made a real mess and was causing product quality problems. Examination of the drains on the dry side of the refrigerated air dryer revealed no free water during these times, but water still mysteriously formed inside the pipes in the plant.

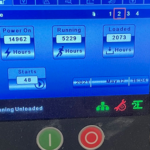

This problem continued off and on until the plant manager called in a compressed air auditor, who hooked up measurement instruments to the system. In addition to monitoring pressure and power, compressed air dew point was also checked over a period of a week. These readings revealed a problem happening during the hottest time of the day, when the compressors were heavily loaded. This, when coupled with the environmental conditions in various areas of the plant, allowed water to form.

The plant was located in an area of the world where daytime temperatures were elevated and ambient humidity was very high. The measurement instruments showed that the air compressors discharge temperatures were in the 120° F range during mid-day because the compressor room was located outside in near 100° heat. The air dryer was not sized for this abnormal temperature and struggled to keep up.

Dryer discharge dew points were peaking in the 80° F range during these times — not high enough to cause free water to form in the dry receiver and filters of the outdoor equipment. Yet, when the air entered the plant, with ambient temperatures in the 72° range due to air conditioning, water condensed out of the compressed air, causing contamination.

The problem was an undersized dryer due to excessive temperatures. A new dryer was sized based on higher worst case conditions, solving the water issue.

Leave a Reply