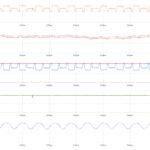

A compressed air auditor was monitoring a system in a plant that produces plastic film. Part of the measurement involved analyzing the flow from the compressor room and the dewpoint of the compressed air. When examining the data, a strange pattern developed on the flow and dewpoint profiles (Fig. 1). We can see the output […]

Air Compressors

One Cajun beef, please, but hold the air compressor oil

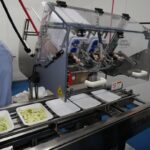

No one wants air compressor oil contaminating production. And in food processing applications, quality and safety are essential. E2M Kitchen, a fresh and ready-to-eat meal provider, knows this all too well. The Charlotte-based company significantly evolved its food preparation and packaging process for creating gluten-free, dairy-free, and preservative-free meals. Every tool used in its production […]

Sauer Compressors announces two new managing directors

Two new managing directors strengthen the management team of the Sauer Compressors Group. The compressor manufacturer has appointed Nicole Fässler as CFO and Mladen Milcinovic as COO as of January 1. As CFO, business economist Nicole Fässler is responsible for the new management area of Finance, HR and IT. The Swiss national has extensive experience […]

Compressed air fail: Unexpected water

It’s always frustrating to find water in a compressed air system, and especially so in locations where the air is supposed to be dry. During a recent compressed air audit, a survey of the piping found that poor dewpoints were being experienced in the system. Investigation found that significant amounts of free water mixed with […]

Compressed air fail: Extra heat

Most of the energy that goes into an air compressor comes out as heat, so it is always a good idea to direct the hot air produced to a location that needs heat — like into a plant in the winter season. The compressor in the photograph has a specially designed heat recovery system that […]

Compressed air fail: Bad water

Water-cooled compressors can have an advantage in locations where the ambient conditions are hot — and therefore using air cooled compressors would result in discharge temperatures that exceed the capacity of the air-drying systems. Overloading air dryers could result in free water entering the plant piping system. This would cause contamination of connected machines and […]

Compressed air fail: A rat’s nest of wiring

An air compressor at a metal processing plant had a troubled life. It started out as a VSD controlled machine, but a fire damaged the controls. Because of this, a new VSD was installed. It didn’t match the old drive, so wiring was altered to accommodate. Next, the drive failed due to dust contamination and […]

High-pressure oil-free compression technology now part of Atlas Copco Group

Hycomp Inc.’s technology has become part of Atlas Copco Group. The company designs, produces, sells and services specialized high-pressure oil-free compressors and boosters for a variety of industries. This is the second such acquisition by Altas Copco, which announced the acquisition of industrial gear pump manufacturer Kracht on January 3. Hycomp is a privately owned […]

Compressed air fail: Quadruple dry

A metal processing company had a laser cutter installed in its manufacturing plant to produce accurately fashioned pieces from metal sheets. This machine requires compressed air that is dried to about 35° F for general use but requires a small amount of air to keep the beam path clean —this avoids contaminating the expensive positioning […]

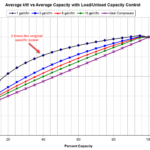

What is a lubricated compressor banana curve?

If you are carefully selecting your new compressors by looking at Compressed Air & Gas (CAGI) data sheets, you should be commended. Use of these sheets are a great way to compare compressor energy and flow characteristics between brands of compressors. In this way, you can choose the most efficient machine for your use and […]