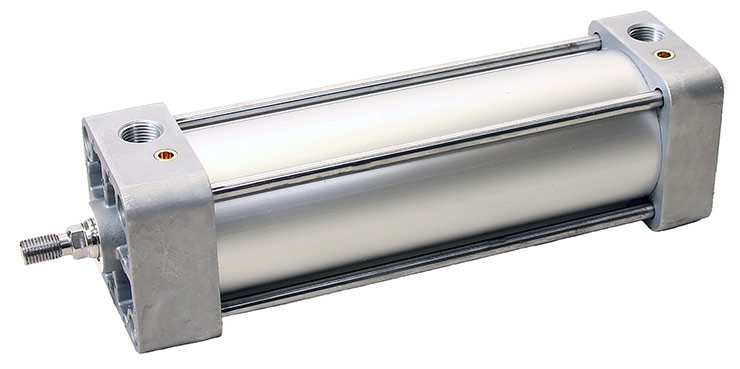

Machine builders and their end-user manufacturers can increase machine speeds and reliability with the new AVENTICS TM5 TaskMaster aluminum cylinder from Emerson. The NFPA-compatible pneumatic cylinder reduces cost, energy consumption, equipment wear and downtime.

With its rugged aluminum body construction and a steel piston rod, the TM5 TaskMaster features Emerson’s state-of-the-art pneumatic cushioning technology that allows an ideal cushion adjustment to slow down the piston to a stop by the time it reaches the endcap. Ideal cushioning reduces the time it takes the cylinder to complete a stroke, allowing an improvement in efficiency that significantly boosts machine speed and lowers endcap hammer. Ideal cushioning also reduces cycle time and enables the TM5 cylinders to carry higher loads without sacrificing cylinder performance.

With its rugged aluminum body construction and a steel piston rod, the TM5 TaskMaster features Emerson’s state-of-the-art pneumatic cushioning technology that allows an ideal cushion adjustment to slow down the piston to a stop by the time it reaches the endcap. Ideal cushioning reduces the time it takes the cylinder to complete a stroke, allowing an improvement in efficiency that significantly boosts machine speed and lowers endcap hammer. Ideal cushioning also reduces cycle time and enables the TM5 cylinders to carry higher loads without sacrificing cylinder performance.

The cylinder incurs less stress and there is no end-of-stroke bounce or end-cap slamming, which is a main source of cylinder wear, slowness and noise. Ideal cushioning thus lengthens cylinder operating life and reduces downtime related to cylinder failure. Additionally, it reduces machine noise and vibration while reducing energy consumption.

“The all-new TM5 TaskMaster gives machine builders and end-user manufacturers the tools to make their machines faster and more reliable,” said James Ward, vice president engineering, machine automation, Americas, at Emerson. “It’s the highest performing and most reliable TaskMaster cylinder ever produced, so it gives them an opportunity to build a competitive advantage.”

The NPFA-compliant TM5 is the latest addition to the TaskMaster line of aluminum cylinders, an industry standard for 50 years. The TM5 TaskMaster is supported by a full suite of web-based design and integration tools, with many products preconfigured and ready to order. With no additional engineering time for setup, Emerson’s online configurator provides a product part number, pricing and 2D and 3D CAD drawings in one convenient place. In addition, all product information and spare parts can be found in the AVENTICS Pneumatics Shop.

TaskMaster TM5 provides a high-quality and readily available interchange cylinder to meet OEM and machine requirements. In combination with the online tools, a fast-delivery program allows for quick turnaround of orders, reducing lead times for customers. From configuration to production, Emerson´s process is completely automated.

Emerson

www.aventics.com/taskmaster

Leave a Reply